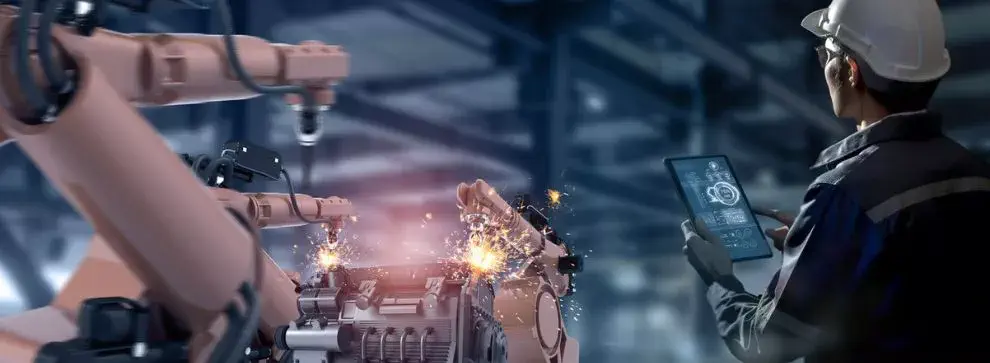

Cobotics is the most promising industrial technology of the last ten years. The term "cobot" officially refers to a "non-autonomous robot, working in direct collaboration with a human, with a view to increasing productivity and reducing the arduousness of its tasks".

WHAT IS A COBOT?

A contraction of the words “robot” and “collaborative”, the cobot is designed to assist humans and work directly with them. It in no way supplants the human being, but rather provides him with safety, comfort and precision in his work, reducing the risk of injury at the same time.

Unlike industrial robotics, which are often characterised by large robots controlled remotely, cobots are smaller, lighter and easily programmable. They are multitasking and can perform a wide variety of missions. In synergy with

humans and under their direct supervision, cobots are able to integrate new information in order to improve the execution of their gestures.

”Human-robot collaboration is 85% more productive than a human or a robot working alone " – MIT study

There are 4 types of cobots :

interaction with it.

For example, the robot has a sensor which detects human presence in its area.

A BOOMING MARKET

Cobotics integrate a wide range of skills including automation, mechanics and IT

technology. It complements industrial robotics. Neuroscientists are now studying cobotics from a cognitive approach. Thanks to sensory receptors and on-board vision, they aim to create dynamic, polyarticulated and intelligent systems to improve fluidity and performance.

In France, ranked second in the world market for cobotics, many sectors have

already adopted it: automotive, food, health and logistics industries. Although their production speed is lower than “classic” robots, cobots are also more economical and less energy-consuming.

”By 2023, the robotics market is expected to reach $5 billion » – Bis Research study

The greatest challenge, and the main factor in the success of this formidable technology, undoubtedly lies in the training, skills development and support of individuals in mastering cobotics.

Cobots are particularly well-suited to logistics: they take up very little space and are used for packaging, pick&place, packing, etc.

With an average return on investment of one year, the cobot is proving to be a rapidly profitable investment.

By freeing themselves from certain tasks, operators can concentrate on higher value-added activities.

By reducing the drudgery and repetition of "thankless" tasks, the cobot helps to improve employee health and reduce work stoppages.

Tell us about your project

Connected intralogistics

As experts of the intralogistics sector, TRANSITIC combines design, development and integration in order to offer its customers effective, consistent and scalable intralogistics solutions.

France

Transitic Systems SAS

96 boulevard du Petit Quinquin CRT 1 – 59812 LESQUIN

Standard : +33 (0)3 20 87 66 96

Support : +33 (0)3 20 87 01 88

Germany

Transitic Systems GmbH

Elpke 107/Halle 50 – 33605 Bielefeld