THE POCKET SORTER: ALL-IN-ONE E-COMMERCE SOLUTION

The e-commerce solution developed by Transitic guarantees you speed and flexibility, and also an efficient response to industry requirements.

The pocket sorter is an overhead sortation system for articles and accessories. It automatically routes, sorts and orders items picked in batches to a packaging station. It is also used to manage returns, which account for 39% of orders in France (source: Statista).

Its compact configuration, modularity and versatility make it one of the most complete and cost-effective intralogistics systems available.

The pocket sorter is a fully automated system that collects, transports, sorts and sequences mass-produced items, whatever their original location and picking method (fixed or dynamic storage, manual or robotised picking). The items then arrive at the workstations in a precise order to be packed.

It’s an all-in-one solution that can handle items such as accessories, footwear, clothing, small parcels and cosmetics at a sustained rate of up to 12,000 items per hour.

These solutions are particularly well suited to e-commerce companies, but can also be used in other sectors, such as retail or logistics. With Pick & Put2Light, any company with varied processes such as picking, kitting or dispatching can manage its orders optimally.

How does the pocket sorter work ?

Made up of hanging pockets (or pouches), usually on hangers or hooks, the pocket sorter uses high-speed overhead conveyors to transport the pockets containing parts to the workstations.

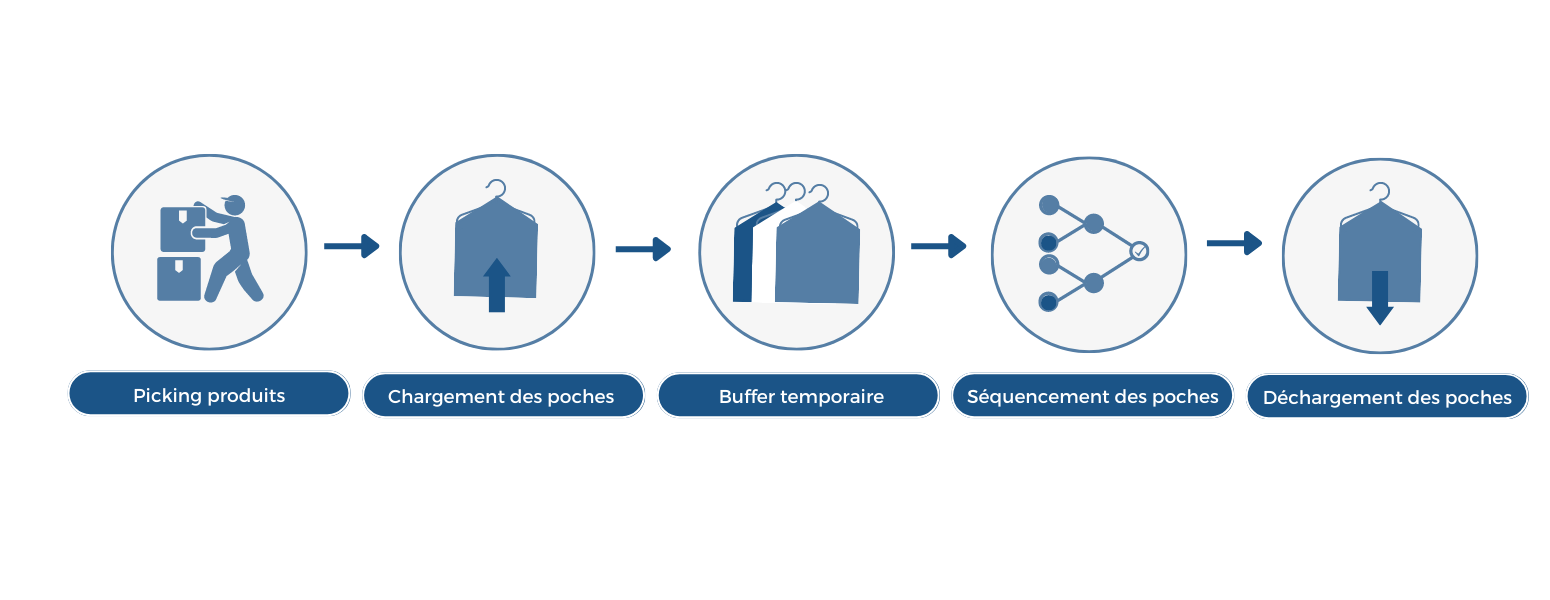

The process is divided into 5 main steps:

Product picking: The main advantage of the pocket sorter is that it enables the operator to pick items without distinction of order. This increases productivity. Picking is done by wave, i.e. by group of customer orders.

Loading the pockets: Once picked, the items are sent to injection stations. Each item is scanned and placed in a pouch, and each pouch has an RFID tag to ensure constant tracking during the sorting process.

Temporary buffer and pocket sequencing: The pockets are automatically routed to a temporary storage area that acts as a buffer. They are then sent to the heart of the system: matrix sorting. Once all the items in the same order are stored in the buffer, this intelligent system uses algorithms to group the pockets according to customer orders.

Unloading the pockets: The pockets are delivered to the operators in a precise order. The items are then unloaded to be repacked in their final packaging. Like injection, this stage can be fully automated.

Why choose pocket sorter?

Respect the goods

A compact, scalable system

Responding to changing flows

Monitoring and control

An intuitive solution with good user acceptance

Durability and maintenance

The main advantages of Transitic's pocket sorter

The Transitic pocket sorter meets all requirements in terms of productivity and precision:

– Increased productivity thanks to an automated system.

– Optimisation of production with an all-in-one solution for transporting, storing, sorting and sequencing orders.

– Reduced operator handling.

– Fewer picking errors thanks to perfect item traceability.

– Optimised order returns.

– Optimise warehouse space with a compact overhead system.

– Reduced maintenance requirements and longer-lasting installation.

– Adaptation of flows and sequencing according to activity.

– Omnichannel, individualised item handling.

– Highly modular installation.

– Complete supervision of the system and its processes using our Open WCS© and Open SCP© software.

Tell us about your project

Connected intralogistics

As experts of the intralogistics sector, TRANSITIC combines design, development and integration in order to offer its customers effective, consistent and scalable intralogistics solutions.

France

Transitic Systems SAS

96 boulevard du Petit Quinquin CRT 1 – 59812 LESQUIN

Standard : +33 (0)3 20 87 66 96

Support : +33 (0)3 20 87 01 88

Germany

Transitic Systems GmbH

Elpke 107/Halle 50 – 33605 Bielefeld