The WCS : 4.0 PERFORMANCE AT THE HEART OF THE SUPPLY CHAIN

The challenges facing the supply chain have never been more numerous or more competitive : last mile deliveries, returns management, shorter delivery times, omnichannel and decarbonization, etc.

Faced with these challenges, connectivity and control of intelligent systems play a determining role in streamlining processes by offering the means to pool operations and adapt flows according to activity and resources.

To do this, WMS and WCS have become essential tools. Last year, the supply chain management software market was worth $20 billion.

While all experts seem to agree that they are essential to productivity, the intrinsic differences between the two software programs are sometimes still poorly understood.

Transitic takes stock of their characteristics, their differences and their advantages.

What is a WCS ?

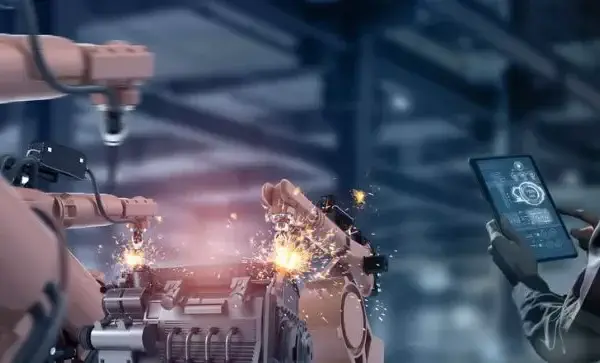

The Warehouse Control System is software used in the supply chain to control and manage automated warehouse equipment. It synchronises all the systems – conveyors, goods-to- persons, robots, AGVs – to ensure they operate at optimum efficiency.

WCS interacts with other systems to adjust resources to customer needs in real time. It coordinates all activities in the installation, including :

– Receiving

– Storage

– Picking

– Packing

– Dispatch

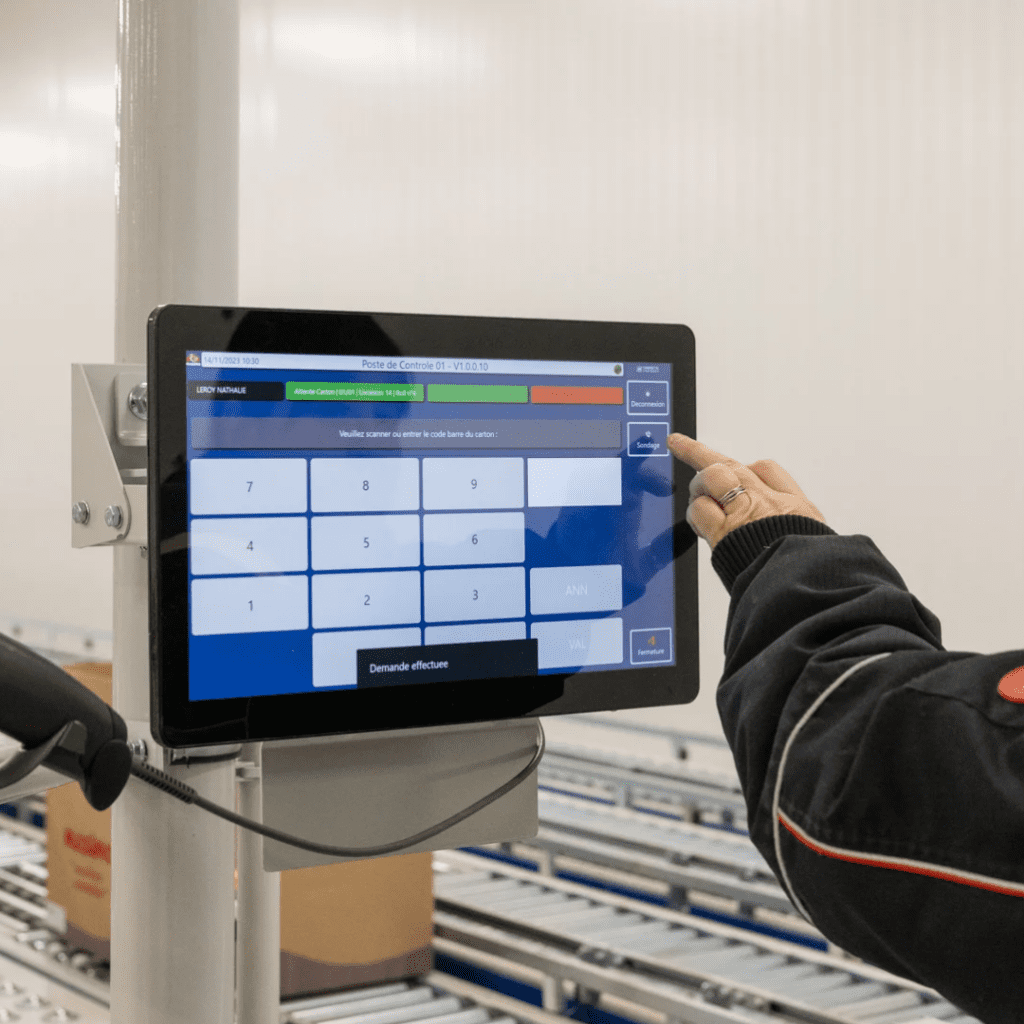

Via its interface with the WMS, it processes in real time information relating to the management and routing of orders. It then dynamically distributes and manages load transfers and sorting according to the defined algorithm, all through screens and a graphical interface that help teams optimize warehouse control.

What is a WMS?

The Warehouse Management System (WMS) is management software that controls and optimises flows and resources within a warehouse. It monitors each individual item and the associated actions.

It allows you to manage all logistics operations via a single interface:

– Stock movements

– Provision of supplies

– Inventory and location management

– Real-time flow planning

– Order and returns processing

What are the differences between WCS and WMS ?

To summarize their functions, the WMS can be likened to the general manager of the warehouse, while the WCS is the operations manager.

However, in an omnichannel context, they tend to become interdependent, with

complementary functionalities that work together to to facilitate warehouse operations.

As a result, most warehouses in the future will be equipped with these two industry 4.0 solutions.

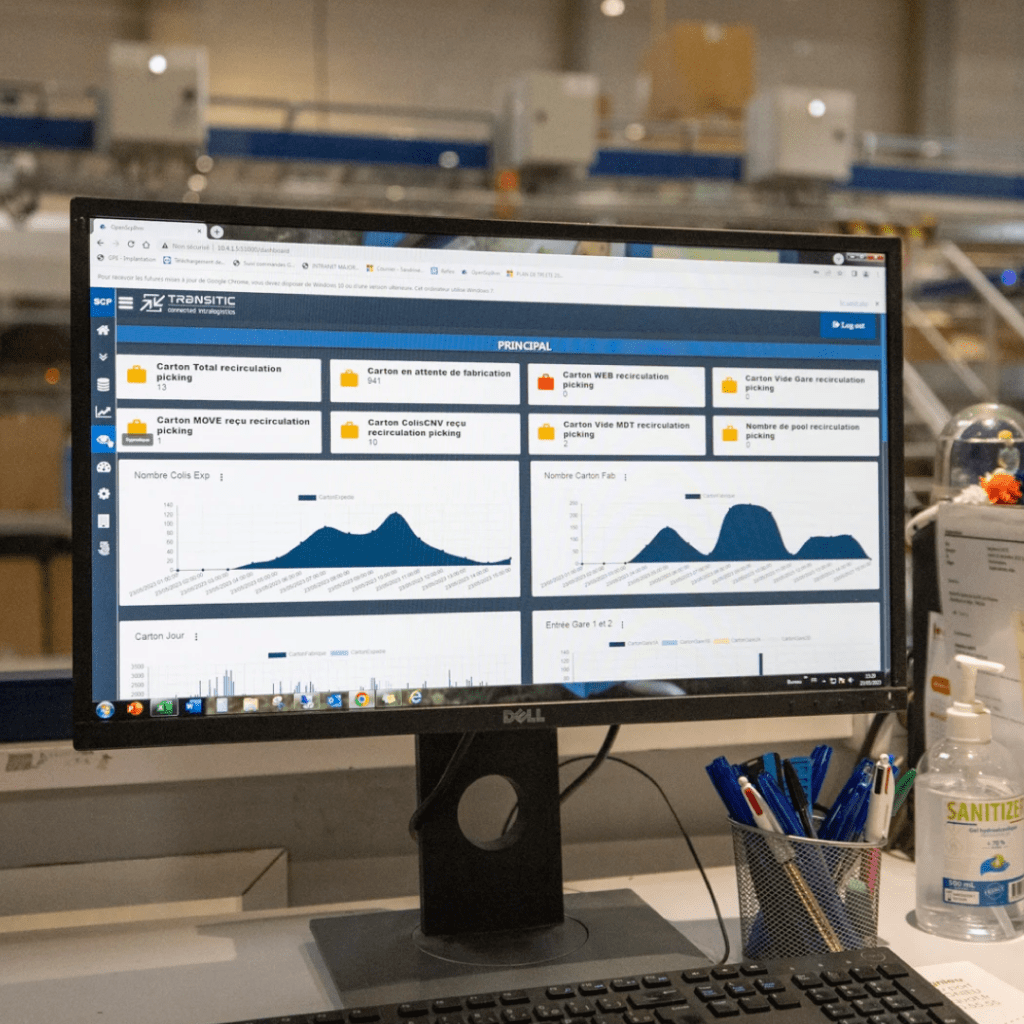

The interconnection between the WMS and the WCS provides optimum coordination between the different stages of goods processing, by providing a 360° map of the state of the installation. Thanks to the WCS interface, supply managers can collect and analyse data, anticipate and rectify activities.

In short, they can regain control of their systems and exploit

them to their full potential.

What features does WCS have?

Warehouse control software is essential to the smooth running of a warehouse. It is the beating heart and the link between the various IT, mechanical and automatic systems. Its flexible architecture allows it to be developed to meet specific customer needs by improving certain functions or even creating new ones.

Here is the main ones :

> Logistics flow control : the WCS provides a simplified HMI (Human Machine Interface) system that allows you to measure, diagnose and correct ongoing logistics operations at a glance.

> Operations planning: : thanks to its algorithm, it sorts and prioritises operational tasks throughout the chain in order to avoid downtime, distribute the load and maximise production:

-Planning orders by storage area or by destination

-Adaptation of routes according to available resources

> Equipment synchronisation: : It coordinates automated equipment to ensure optimum flow of goods.

> Inventory and space management: : The WCS tracks the entry and exit of goods into automated storage and uses algorithms to optimise their location according to their frequency of rotation.

> Decision-making support: It provides real-time monitoring of processes and global visibility of the warehouse, enabling you to react quickly and readjust production in response to changes in demand or unforeseen events.

> Global system communication: :WCS integrates seamlessly with most ERP and WMS systems on the market, ensuring complete synergy and coordination of all supply chain systems.

What are the benefits of WCS?

It increases order-picking accuracy and reduces the risk of errors

WCS improves operational efficiency by reducing operating costs

It optimises storage space thanks to precise stock management

It enables immediate responsiveness to changes in demand

Streamlines processes by reducing turnaround times

It contributes to customer satisfaction through shorter delivery times

Optimising supply chain management with OpenWCS by Transitic.

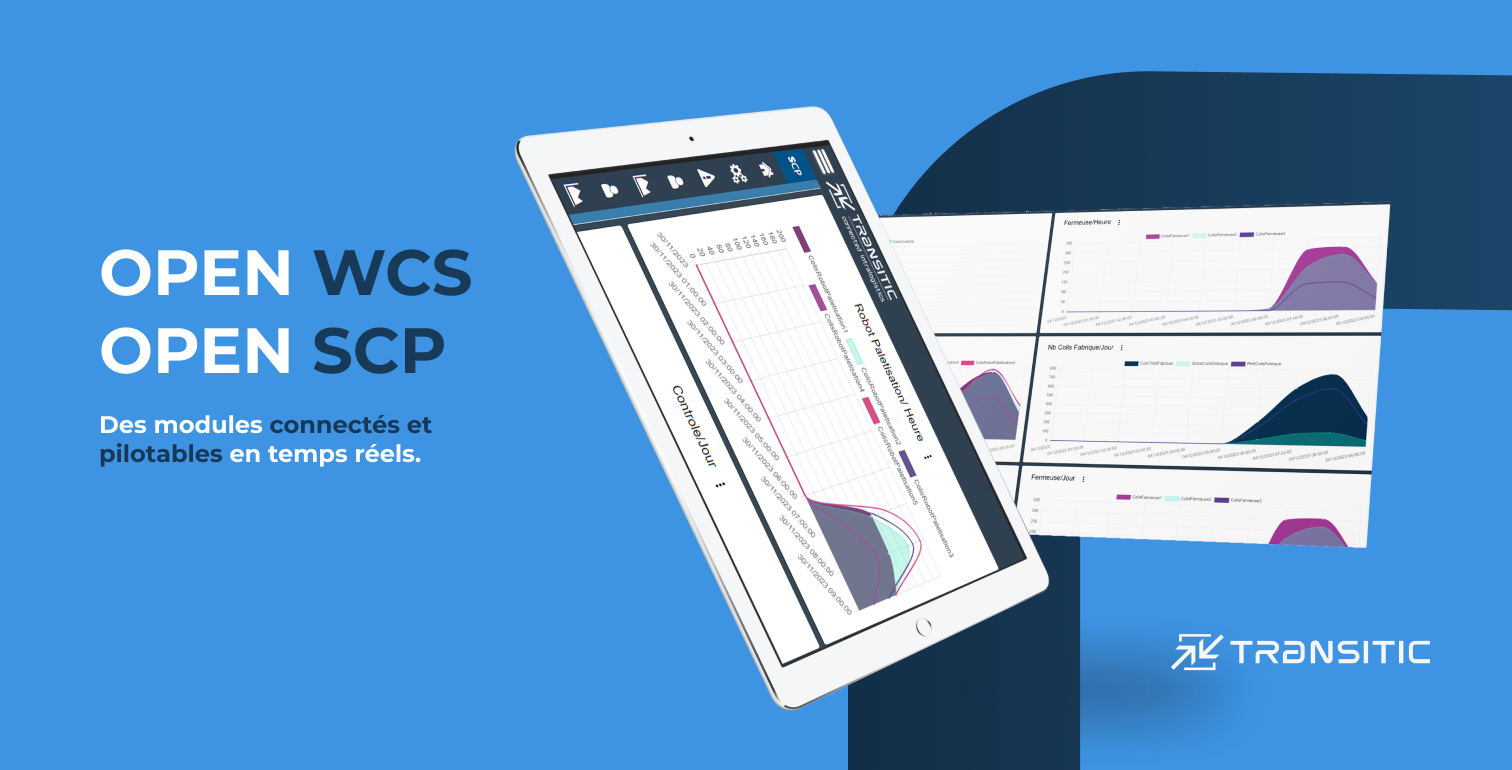

Transitic offers OpenWCS, a systems control and supervision solution that coordinates the various automated processes.

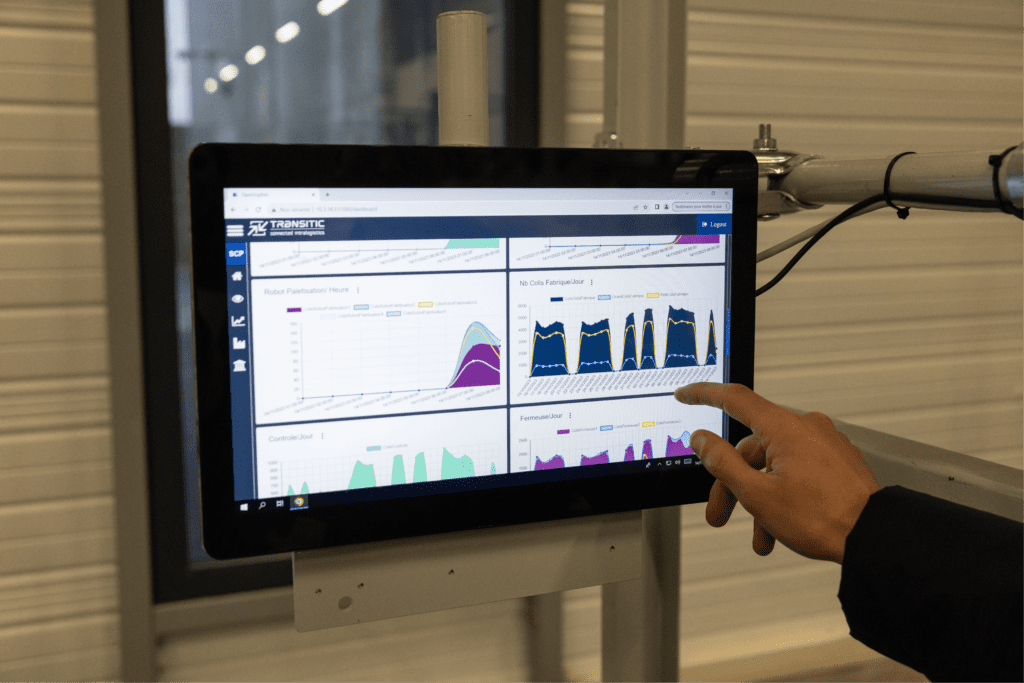

Operational and agile, it is agnostic software that adapts to any type of existing or future system. Our IT teams are constantly working on its scalability to respond to and anticipate the changes of Industry 4.0: ergonomic and customised interfaces, multi-support access, predictability of anomalies, etc.

Interconnectivity

OpenWCS interconnects with all types of WMS and ERP, whatever the communication protocol.

Traceability

It guarantees rigorous traceability of products and associated logistics processes.

Resource analysis

It takes into account physical flows, resources and customer data.

Productivity

It measures, diagnoses and optimises the productivity of each automated system.

Efficiency

It improves the efficiency of all systems and reduces production costs.

Scalability

It enables a scalable, more connected and intelligent supply chain.

Open Source

With no licence required, it delivers a rapid return on investment.

OpenWCS can be complemented by Transitic’s OpenSCP software, a flow monitoring solution and decision support tool, available on mobile, PC or tablet devices.

OpenSCP (Supervision Control Panel) gives you global visibility of performance indicators and allows you to monitor all your activities in order to react quickly to any operational needs.

It is fully configurable and personalized according to the desired KPIs, and ensures synergy with new Industry 4.0 technologies (automates, M2M, etc.).

Tell us about your project

Connected intralogistics

As experts of the intralogistics sector, TRANSITIC combines design, development and integration in order to offer its customers effective, consistent and scalable intralogistics solutions.

France

Transitic Systems SAS

96 boulevard du Petit Quinquin CRT 1 – 59812 LESQUIN

Standard : +33 (0)3 20 87 66 96

Support : +33 (0)3 20 87 01 88

Germany

Transitic Systems GmbH

Elpke 107/Halle 50 – 33605 Bielefeld