WES vs WMS vs WCS: Understanding their differences and how they complement each other to optimise your warehouse

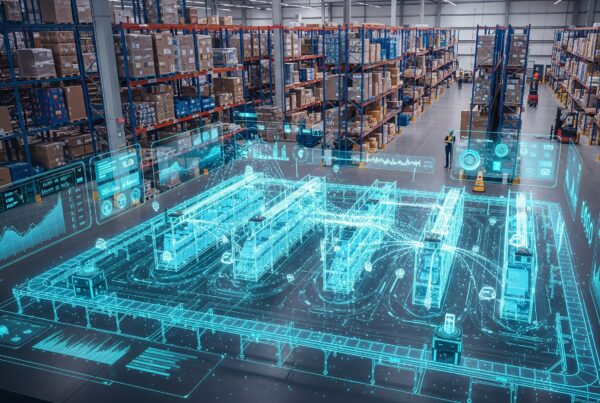

With the widespread adoption of automation in warehouses, Warehouse Execution Systems (WES) have become essential to ensure seamless integration between automated processes and human operations. These supply chain software solutions, which act as a bridge between Warehouse Management Systems (WMS) and Warehouse Control Systems (WCS), help optimize workflows, improve operational efficiency, and address the challenges of Intralogistics 4.0.

Summary of the article

The Warehouse Execution System (WES) stands out as the crucial link between the WMS and the WCS. Acting as a true operational conductor, it optimizes flows in real time, coordinates both human and machine resources, leverages AI to anticipate needs, and ensures smooth order execution. Complementing both the WMS and the WCS, the WES lies at the heart of Intralogistics 4.0, delivering performance, flexibility, and responsiveness.

01. What is WES software?

A Warehouse Execution System (WES Software) acts as the “operational brain” of the warehouse. It is designed to coordinate and optimise all warehouse flows by integrating both automated processes and tasks carried out by human operators. It ensures continuous order execution by making the best use of available resources.

WES software is now essential for managing the increasing complexity of logistics operations. It effectively orchestrates robots, conveyors, sorting systems, order-picking systems, and automated machines—providing a true competitive edge.

02. What are the differences between WES, WMS, and WCS?

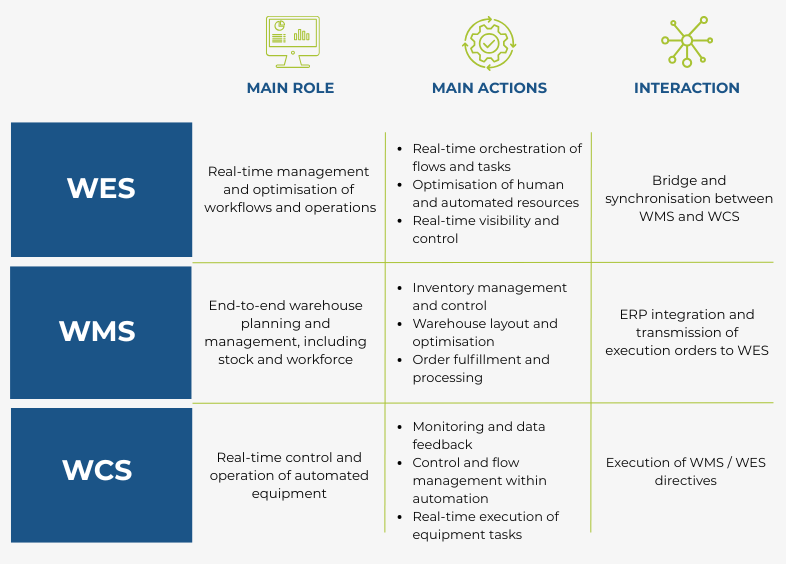

WES differs from other warehouse management systems like WMS and WCS. While these three types of supply chain software can complement one another, it’s important to understand their distinct roles and scopes:

WMS (Warehouse Management System):

A WMS handles inventory management, storage space organisation, and control of logistics flows. It provides an overview of inventory and shipments, and assigns tasks to human operators.

WCS (Warehouse Control System):

A WCS manages and coordinates the warehouse’s automated equipment. It synchronises all systems (conveyors, Goods-to-Person systems, robots, AGVs, etc.) to ensure optimal operation.

WES (Warehouse Execution System):

Sitting between WMS and WCS, WES orchestrates workflows and synchronises resources, whether human or automated. It ensures fast and seamless order execution.

03. Key features of WES

The WES software plays an increasingly vital role in modern warehouses, where collaboration between robots and humans is becoming the norm. By 2027, over one in four warehouses will be automated (Source: Mordor Intelligence). This shift highlights the need for hybrid software solutions like WES, which ensure synergy between inventory management, processes, and human operators.

Here are its main features:

Workflow and order fulfillment optimisation

WES stands out for its ability to analyse various order picking stages in real time. It prevents bottlenecks by dynamically prioritising and allocating workflows. It defines picking and routing strategies—assigning tasks to specific zones or systems based on available resources.

AI-Driven planning

With artificial intelligence (AI), WES can anticipate and adapt to unexpected events. For example, in case of a delivery delay, it automatically reprioritizes tasks to maintain workflow continuity. AI also allows simulation of various scenarios to improve planning during peak periods.

Accurate inventory management and real-time traceability

WES enhances inventory accuracy through RFID systems, ensuring 360° visibility of goods movement. Depending on inventory levels, the software can automatically trigger restocking.

Optimal coordination between humans and machines

WES facilitates interaction between human operators and automated equipment—including robots—by assigning tasks based on performance and workload.

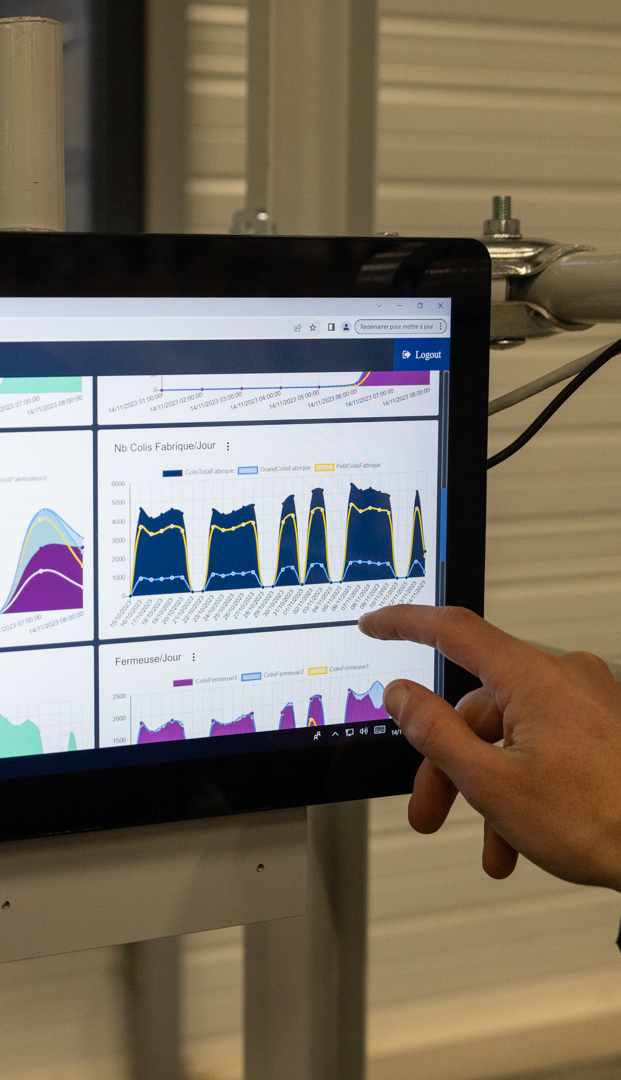

Proactive analysis and predictive maintenance

By leveraging real-time data, the system can anticipate potential malfunctions. It raises alerts in case of anomalies and schedules maintenance to minimise downtime.

Seamless integration with other IT systems

WES integrates effortlessly with other systems like WMS and WCS. This interconnectivity places it at the center of the intralogistics ecosystem, ensuring smooth and coherent data exchange.

04. Toward an all-in-one system?

Technological evolution is leading to a convergence of functionalities. WES is already incorporating features from WMS and WCS, such as planning and real-time supervision. This raises an important question: could WMS and WCS softwares become obsolete? Are we moving toward a single unified system that combines inventory management, automation, and workflow orchestration?

In the short term, it’s unlikely that WES will fully replace these systems. For now, they complement each other and benefit from each other’s strengths:

> Le WMS se charge de la gestion des stocks tandis que le logiciel WES ensures optimal task execution by allocating resources and prioritising orders based on needs. Together, they optimise flows and reduce processing errors.

> Le logiciel WCS controls automated equipment (conveyors, robots, AGVs), while WES coordinates their use. Their synergy enables real-time optimisation of goods movement, ensuring maximum efficiency and reducing downtime.

About the Author – Frédéric Cousin

Frédéric Cousin works at Transitic as Sales Manager for Intralogistics & WCS. With significant experience in the supply chain sector, Frédéric spent over 10 years with several well-known software vendors. He also held a logistics manager position for 7 years.

Subscribe to our newsletter

A concentrated dose of intralogistics! Discover our latest business cases, videos, and news.

Related Articles

#connectedintralogistics

France

96 Bd du Petit Quinquin

CRT 1 – 59812 Lesquin

Tél. : +33 (0)3 20 87 66 96

Germany

Am Scheid 1

57290 Neunkirchen

Tel : +49 2735 6588580

Spain

C/ Velazquez, N. 80 – 5 IZ

28001 Madrid

Tel : +34 673 234 296