Transitic x Maximo

Transitic déploie un système intralogistique innovant pour Maximo

TRANSITIC a conçu et installé un système intralogistique global sur près de 17 000 m² pour le compte de MAXIMO, spécialiste de la livraison de surgelés. Un concentré d’innovations au service de la performance où convoyeurs, machines automatiques et robots fonctionnent en synergie dans le plus strict respect de la chaîne du froid.

Projet

Système intralogistique global

Client

Maximo

Lieu

Alençon, Normandie, France

Maximo est une entreprise agro-alimentaire spécialisée dans la livraison de produits surgelés à domicile. Créée en 1893, cette société familiale basée à Reims a su moderniser son concept au fil des décennies et compte aujourd’hui plus de 500 000 clients. Elle possède une cinquantaine d’établissements en France approvisionnés par deux grands centres de préparation de commandes.

Un nouvel établissement

En 2023, Maximo a inauguré un nouvel entrepôt logistique à Cerisé aux portes d’Alençon. D’une superficie de 17 000 m², cette plateforme logistique a pour objectif « d’optimiser les flux logistiques, d’améliorer les postes et les conditions de travail (robotisation, ergonomie…) et ainsi gagner en productivité. » selon Eric Balon, directeur logistique du groupe.

Maximo a choisi Transitic pour équiper ce nouveau centre et atteindre les objectifs de croissance fixés. Les deux sociétés avaient déjà collaboré avec succès sur un système Pick-to-Light embarqué au sein de de la seconde plateforme logistique située à Verdun.

Une solution de stockage adaptée

1200

6

1200

Un projet intralogistique global au service de la performance

Transitic a assuré la fabrication et le déploiement d’un système global destiné à la préparation, l’identification et l’expédition des commandes clients. Un réseau de convoyeurs de plus d’un kilomètre de long parcourt l’intégralité de l’entrepôt pour alimenter toute la chaîne de préparation.

1. Machines automatiques en zone de lancement

Deux formeuses de cartons multiformats ont été placées en zone de lancement. Une étiqueteuse et un scanner de contrôle s’assurent de la traçabilité de chaque carton. Ces derniers sont ensuite acheminés vers la zone de picking.

2. Système Pick-to-light en zone de picking

1 150 systèmes Pick-to-Light, composés de voyants lumineux et écrans digitaux, ont été installés afin de guider les opérateurs dans le prélèvement des produits. Ils sont complétés par des écrans de contrôle et des scanners qui assurent un suivi permanent des commandes.

3. Convoyeur de déchets cartons

Plus de 16 000 cartons fournisseurs sont consommés chaque jour dans l’entrepôt. Un convoyeur aérien à bandes a donc été prévu le long de la ligne de préparation pour permettre aux opérateurs d’évacuer rapidement les cartons vides vers des compacteurs.

4. Postes de contrôle et fermeture des cartons

Une fois le prélèvement des produits terminé, chaque carton circule sur une balance dynamique avant d’être envoyé vers 3 postes de contrôle assistés. Transitic a apporté une attention particulière à leur ergonomie afin de réduire la pénibilité des tâches. Les cartons sont ensuite conduits vers des fermeuses et cercleuses automatiques.

5. Buffer séquenceur en zone grand froid

Un buffer-séquenceur a été implanté dans une zone à -25 degrés. Composé de 10 lignes de convoyeurs, il permet de trier les commandes selon leur tournée de livraison et de stocker les cartons en attente de transfert. « Le gain de productivité apporté par ce système est considérable et supprime les contraintes de séquencement en amont. » ajoute Jérôme Paque.

6. Robots palettiseurs

Une fois sortis du buffer, les cartons sont chargés automatiquement dans des roll-conteneurs grâce à 5 robots palettiseurs. Ces derniers fonctionnent dans un environnement réfrigéré à 5 degrés. Ils respectent l’ordre de livraison des cartons avant leur chargement dans les camions.

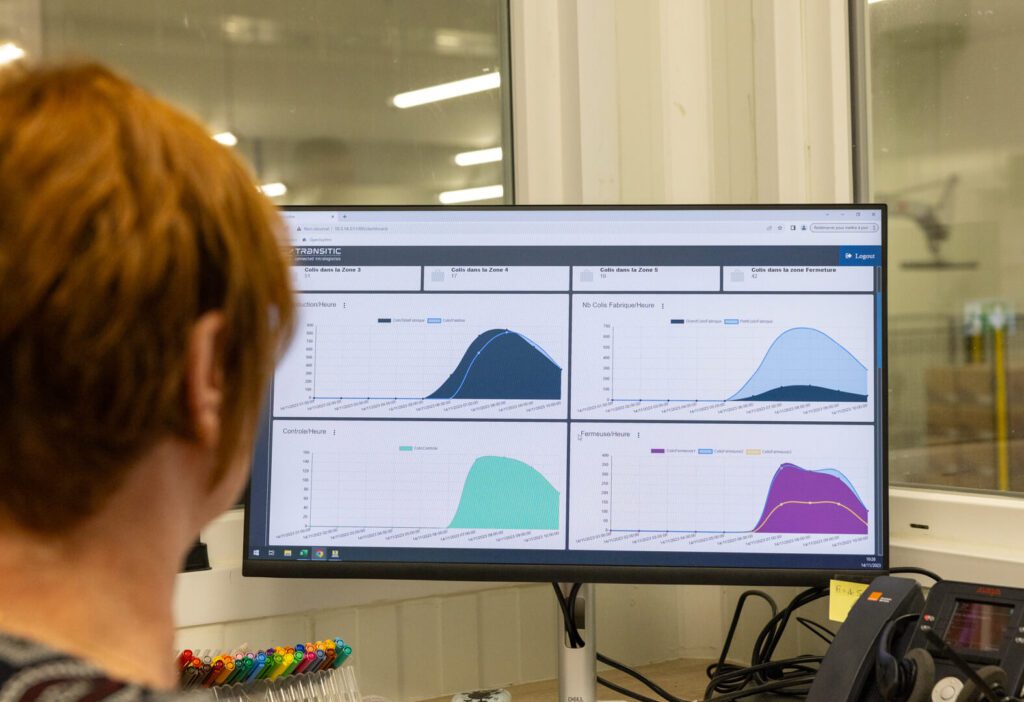

7. Un pilotage informatique des systèmes

L’ensemble du système – convoyeurs, machines et robots – est piloté par la suite logicielle Open WCS. Elle supervise les différentes installations automatisées, coordonne le routage des flux et le lancement des commandes. Ce logiciel complet permet également un pilotage en temps réel du système grâce à une interface intuitive et des indicateurs de performance personnalisés.

Une installation adaptée aux exigences du secteur agroalimentaire

Fort de son expérience dans le secteur de l’agro-alimentaire, Transitic a veillé à ce que l’installation respecte scrupuleusement les normes de sécurité et d’hygiène et la continuité de la chaîne du froid. Ainsi, le choix des matériaux, qu’ils soient mécaniques ou électroniques, a été primordial afin de s’assurer de leur fonctionnement à long terme dans les zones fonctionnant à -25 degrés. Une attention particulière a également été portée à la consommation énergétique du système et sa facilité de maintenance et nettoyage.

Découvrez notre installation en vidéo !

LES POINTS FORTS DE L’INSTALLATION TRANSITC

Un système global avec des prestations mécaniques et automatiques, coordonnées simultanément par des logiciels fonctionnels et agiles.

Une offre adaptée aux contraintes de Maximo, notamment la résistance des machines dans des environnements à basse température et le respect de la chaîne du froid.

Des installations pensées pour améliorer la productivité, diminuer la pénibilité de travail et limiter le nombre d’erreurs dans la préparation des commandes.

”Pour ce projet, nous avons fait appel à l’ensemble de nos savoir-faire avec des prestations mécaniques, électroniques, informatiques ou encore robotiques.»

Jérôme PaqueDirecteur de projet Transitic

Les systèmes clés de l'installation

Le bras robotique

Également appelé robot palettiseur, cet équipement manipule des charges lourdes tout en organisant les cartons, par exemple selon leur transporteur. Le bras robotisé soulage les opérateurs des tâches pénibles et garantit une cadence de travail régulière et continue.

Le buffer séquenceur

Le buffer séquenceur permet de stocker et d’ordonner une large quantité de marchandises et cartons dans l’attente de leur expédition. Dans le secteur agroalimentaire, il se trouve le plus souvent dans des zones réfrigérées, évitant ainsi toute rupture de la chaîne du froid.