Transitic x Cergy Vis

Design of an automated network of flat and vertical conveyors to streamline order picking

Project

Automated conveyor network

Client

Cergy – Vis

Location

Île-de-France, France

The client

Founded in 1979, CERGY-VIS specialises in online sales of screws, bolts and other fasteners. The company, which caters for both professionals and private customers, currently has 3 e-commerce sites (Cergy-Vis, Bricovis and Fix’N’Vis) as well as a physical sales outlet near Paris. With more than 50,000 products and 150,000 customers, CERGY-VIS has enjoyed a boom in recent years.

The project

The CERGY-VIS multi-storey warehouse is divided into 5 separate order preparation areas. The company wants to be able to easily group together these different parts of the order in order to finalise the parcels in a single location and then route them to the dispatch area, located on level n+1.CERGY-VIS wants to increase its production capacity and prepare more orders in less time. To this same end, the company is also seeking to reduce the number of journeys made by its operators.

The solution

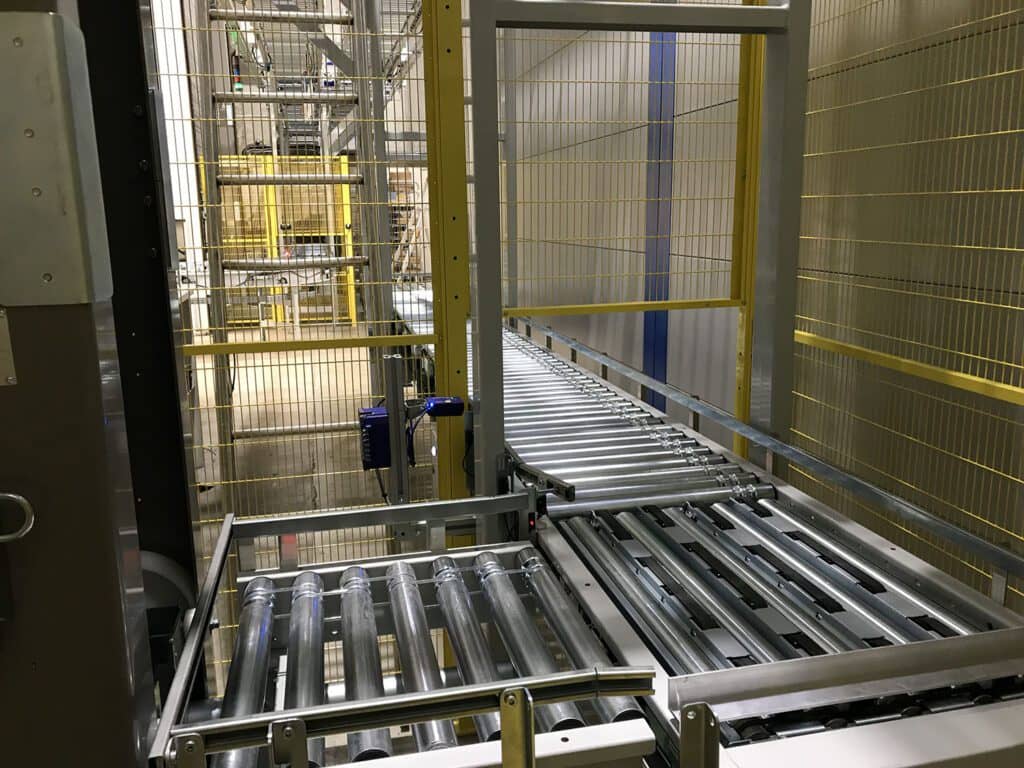

Order preparation is divided into 5 separate areas. These parts of orders, identified by a barcode, are then transported by vertical conveyors to a carousel located on level n+1.

The carousel is made up of roller conveyors and transfer conveyors. It can handle up to 66 boxes simultaneously. Equipped with a scanner, it detects when all the components of the same order are in circulation. At this point, they are sorted and removed.

A vertical conveyor then routes them to one of the various order grouping stations. The order can then be checked and packed. Once the final carton has been manually strapped and labelled, it is placed on a conveyor, scanned and directed to the dispatch area.

25

”The solution is designed to be scalable: thanks to the Open WCS software, the system is controlled in real time and can be interconnected with all existing or future mechanisms. It's a long-term, reliable choice for CERGY VIS."

The key systems of the installation

Vertical conveyor

Also known as a lift conveyor or pallet elevator, this equipment enables the use of multi-level warehouse layouts. Thanks to its robust design, it ensures high throughput, providing smooth and continuous transfer of goods between floors.

Open WCS

Open WCS© allows you to interconnect your various automated systems and subsystems involved in managing your logistics flows in coordination with a WMS. This software suite provides supervision and monitoring of all automated processes within your warehouse.