Top 5 Most Efficient Systems for Batch Picking Automation

Summary of the article

The article highlights the importance of batch picking in logistics to optimize travel and improve productivity. Transitic presents a top 5 list of the most effective automated systems for batch picking. These systems provide significant time savings, reduce errors, and improve the ability to handle peak activity periods.

Choosing the right solution depends on order volume, warehouse layout, and SKU turnover. The role of the intralogistics integrator is crucial to select the most suitable method and oversee deployment.

01. Batch Picking as a Driver of Logistics Efficiency

With an average online order of 3.89 items (source: Dynamic Yield), warehouse operators walk miles to locate and collect scattered SKUs. This daily marathon affects productivity, service quality, and delivery times.

To maximize order fulfillment efficiency, companies aim to eliminate unnecessary tasks and movements. Batch picking provides a concrete solution: it streamlines flows through automation and traceability tools.

We invite you to explore this strategy that is redefining warehouse organization and share our top 5 best solutions to automate it.

02. Batch Picking Methods Tailored to Each Activity

In intralogistics, batch picking (also called “picking by batches”) involves grouping the preparation of multiple orders or SKUs instead of handling them individually.

In practice, the operator completes a single run to collect all SKUs for several orders. After collection, items are sorted and assigned to their final destinations.

There are several batch picking methods, adaptable depending on warehouse conditions and the specific needs of each business:

- Manual batching: The operator collects items from multiple orders in a single run manually, then sorts and assigns them to each final order.

- Wave batching: Picking is organized in time-based waves. Orders are grouped according to time or logistics criteria (truck departure time, client type, geographic zone, etc.).

- Zone batching: Orders are grouped when they involve picks in the same warehouse zones, optimizing the work of operators assigned to those areas.

- Pick-and-Pass: This strategy combines batch and zone picking: each operator works in a specific warehouse zone and passes partially completed batches to the next zone.

Batch picking is now the standard in modern warehouses, especially in high-volume sectors like e-commerce, fashion, and retail. Ideal for small to medium-sized similar products, it is less suitable for bulky items or those requiring special handling.

03. Measurable Benefits for Increased Productivity

Without a strategy to consolidate orders, warehouses face performance bottlenecks. Operators’ back-and-forth trips can account for up to 60% of picking time (source: Logistics Bureau). Combined with repetitive handling and human errors, the entire supply chain can be affected.

Batch picking addresses most of these issues:

- Time optimization: It consolidates picks from multiple orders into a single run, reducing operator travel by 40% (source: Zebra).

- Productivity gains: It increases order throughput by up to 50% with the same workforce (source: Reflex Logistics).

- Peak activity management: It helps teams handle volume surges better by optimizing routes and processes.

- Fewer errors, more traceability: Through WMS/WCS, it ensures accurate traceability, adjusts stock in real time, and reduces picking errors by threefold.

04. Top 5 Best Batch Picking Systems for Maximum Efficiency

The automated picking market currently grows around 9% annually (source: Statzon). New solutions are emerging to boost productivity, ensure operational reliability, and relieve operators from repetitive tasks.

Here is our top 5 list of the most efficient automated systems:

1. AS/RS Systems (Automated Storage and Retrieval Systems)

These automated systems optimize vertical space and access speed. Using shuttles or miniloads, they pick required SKUs in advance and intelligently group them for picking stations, providing an effective Goods-to-Person solution.

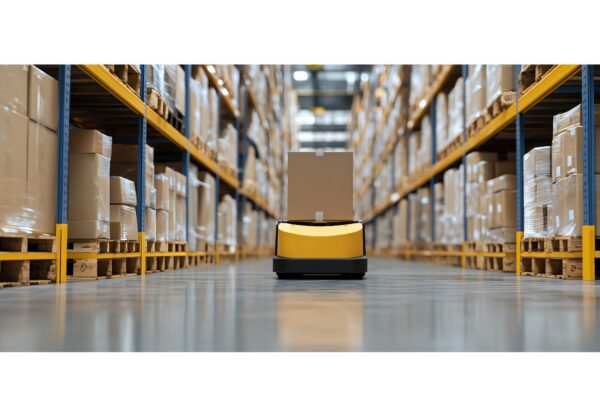

2. Autonomous Mobile Robots (AMRs)

AMRs automate and streamline the connection between storage zones and picking stations by transporting bins containing products for multiple orders. Flexible, they adapt to layout changes and reduce operator travel time.

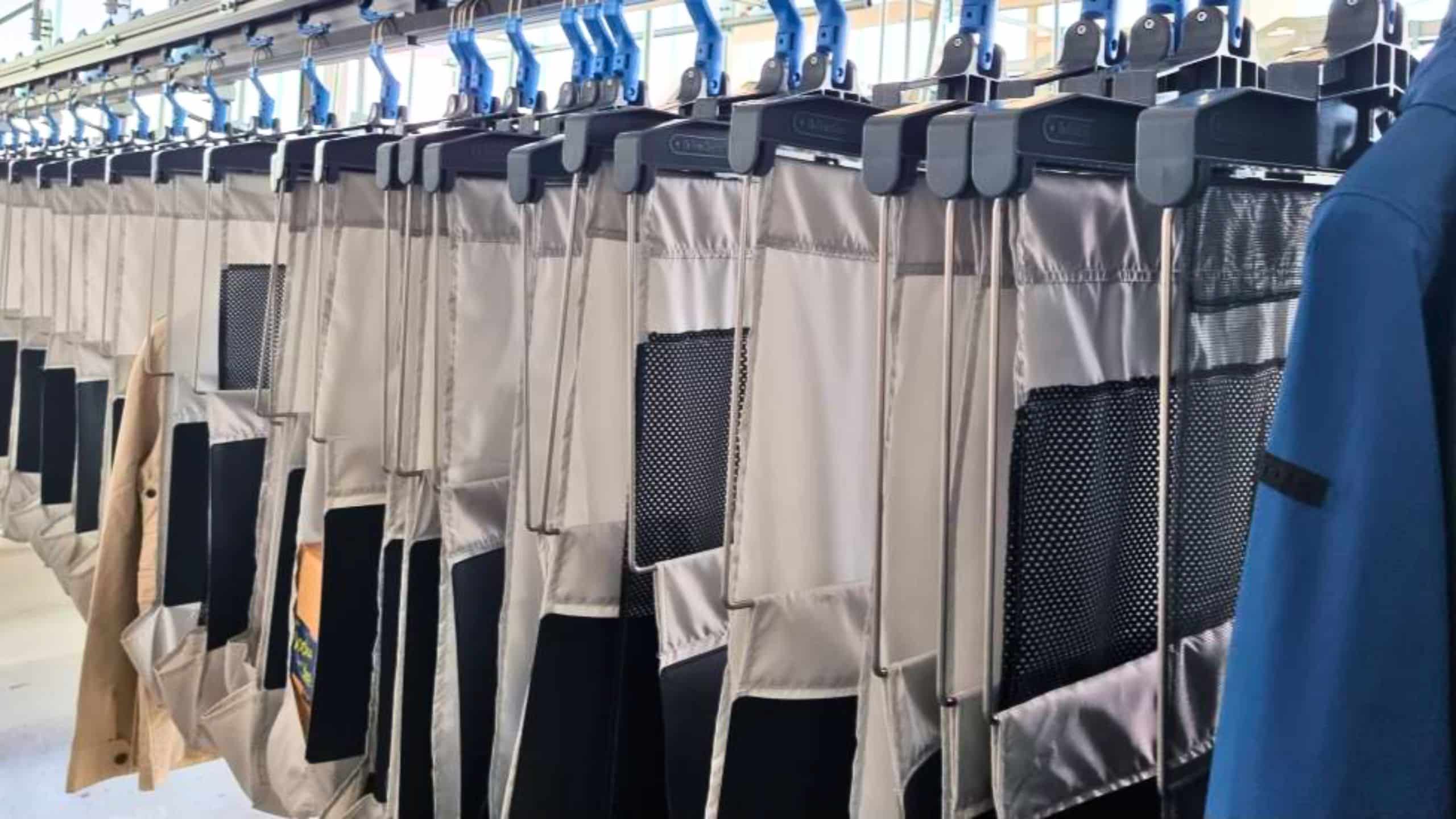

3. Pocket Sorter

The Pocket Sorter is an all-in-one overhead solution perfectly suited for high-speed batch picking (up to 12,000 items/hour). After bulk unsorted picking, each item is inserted into a suspended pouch, scanned, and automatically transported. The pouches are then reordered to group items by order, ensuring high accuracy and speed without manual intervention.

4. Pick-to-Light and Put-to-Light (PTL) Systems

These assisted solutions offer a great balance between performance, cost, and simplicity. Lights guide operators either to item locations for picking (Pick-to-Light) or to sorting bins for batch allocation (Put-to-Light). They are easy to integrate and require a limited investment.

5. Picking Robots or Robotic Arms

Robotic arms perform individual picks from bins prefilled automatically by AS/RS or delivered by AMRs. With the ability to recognize and handle different items, they can distribute SKUs to multiple orders, significantly reducing human intervention and errors.

Batch picking supports continuous improvement of flows and processes. ROI for each solution depends on initial cost but is typically achieved in 2–5 years through operational gains and lower operating costs.

05. Deploying a Batch Picking Project: The Role of the Integrator

Although it may seem straightforward, implementing a batch picking strategy can be more complex than it appears. It involves the entire order fulfillment chain and may reveal process inconsistencies.

An intralogistics integrator like Transitic can help assess existing operations and identify the most suitable picking method for your business, based on parameters such as:

- Daily order volume

- Number of SKUs in stock and turnover rate

- Seasonal or occasional activity fluctuations

- Warehouse layout (size, zoning, stock distribution)

With a holistic view of intralogistics processes, the integrator can ensure rapid and smooth deployment with minimal production impact.

They can also advise on upgrading technological tools and warehouse management software (WMS and WCS) to collect and leverage key real-time data. This data enables you to measure the concrete impact of your strategy and implement further improvements if needed.

About the author – Cloé Moreel

Cloé Moreel has been a communications officer at Transitic since 2020. She regularly writes articles on intralogistics, supply chain, and emerging connected technologies.

Subscribe to our newsletter

A concentrated dose of intralogistics! Discover our latest business cases, videos, and news.

Related Articles

#connectedintralogistics

France

96 Bd du Petit Quinquin

CRT 1 – 59812 Lesquin

Tél. : +33 (0)3 20 87 66 96

Germany

Am Scheid 1

57290 Neunkirchen

Tel : +49 2735 6588580

Spain

C/ Velazquez, N. 80 – 5 IZ

28001 Madrid

Tel : +34 673 234 296