Roller Conveyors: The Complete Guide to Optimizing In-House Warehouse Transport

Summary of the article

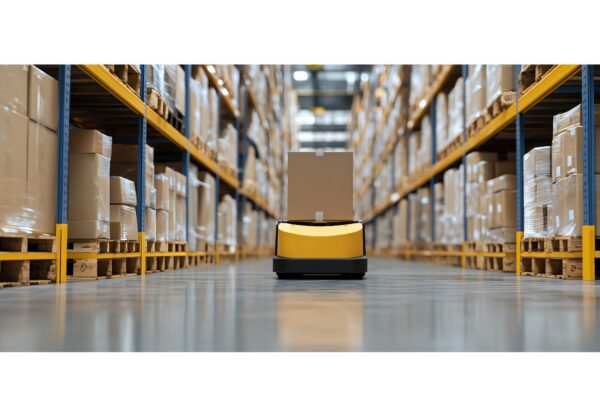

In logistics environments, the movement of parcels, bins, or pallets directly impacts operational performance. Automating these flows not only boosts productivity but also enhances operator safety and comfort. Roller conveyors provide a simple, robust, and modular solution to optimize the movement of loads at a controlled cost.

01. What is a roller conveyor?

A roller conveyor is a transport system made up of a series of rollers that allow parcels, totes, boxes, or any other product to move continuously from one area to another within a warehouse, a production line, or an order-picking center.

The movement can be carried out in several ways: by gravity, by manual push, or using powered rollers. This flexibility makes it one of the most widely used solutions in intralogistics.

The main advantages of these systems are:

Thanks to their modular design, roller conveyors adapt to any layout and can be combined with other automated systems for smooth internal flow management.

02. The different types of roller conveyors

1. Flat roller conveyor

The flat roller conveyor conveyor is particularly suited for manual lines or low-throughput areas, where operators move loads by pushing them.

Advantages: low cost, quick deployment, minimal maintenance

Advantages: low cost, quick deployment, minimal maintenance.

2. Powered roller conveyor

Designed for automated lines and high‑throughput environments, the powered roller conveyor ensures smooth, precise, and continuous transport of loads. Each section of the conveyor can be controlled independently, enabling intelligent flow management: accumulation, transfer, sorting, or synchronization with other equipment.

Advantages: controlled throughput, optimized production, reduced handling.

3. Gravity roller conveyor

It uses natural slope to move cartons or parcels without any motorization. Ideal for buffer storage, sorting, or order preparation areas, the gravity conveyor helps reduce energy consumption.

Advantages: quiet, economical, durable.

4. Telescopic roller conveyor

Easy to deploy, it is ideal for receiving and shipping areas, where layouts frequently change depending on activity levels. Mounted on wheels and adjustable in length and orientation, it allows for the quick creation of temporary lines for loading, unloading, or sorting parcels. It can be powered or manual.

Advantages: flexible, ergonomic, easy to use.

Need roller conveyors in your warehouse? Transitic is here to support you!

03. The technical advantages of roller conveyors

Roller conveyors are much more than simple transport systems: they optimize internal flows, reduce operating costs, and improve warehouse productivity.

Reliability and performance

They ensure smooth transport of bins or cartons while minimizing handling for operators. Reliable and proven, they offer a quick return on investment.

Reduced Maintenance

Without pneumatic components, the installation is quiet and easy to maintain. Materials are chosen for each sector: stainless steel for food and pharmaceutical industries, and enhanced durability for cold storage environments.

Scalability and flexibility

Roller conveyors can easily retrofit existing installations without major modifications. Directional modules allow for complex networks with curves and elevated sections. The Stop & Go feature helps save energy on powered lines.

Connectivity and automation

These systems integrate with WMS and WCS software, providing precise flow control and enabling seamless synchronization with warehouse operations.

Productivity gains

Roller conveyors allow warehouses to improve their overall performance by 20 to 40% thanks to:

- Optimized movement: reducing internal transport times by nearly 34% (Global Growth Insights).

- Reduced handling by 30 to 40%, freeing operators for higher‑value tasks.

04. Why choose Transitic for your roller conveyors?

Every company has its own requirements: type of loads, required throughput, building layout, hygiene or safety constraints…

At Transitic, we design and integrate custom roller conveyors. Our systems fit seamlessly into existing lines or automated facilities, including AGVs, AMRs, robots, or WMS systems.

About the Author – Adrien Gislain

Adrien Gislain has been working at Transitic as Customer Solutions Manager since 2021. With over 10 years of experience in logistics, both in France and internationally, he is recognized as an expert in Intralogistics 4.0 and robotics.

#connectedintralogistics

France

96 Bd du Petit Quinquin

CRT 1 – 59812 Lesquin

Tél. : +33 (0)3 20 87 66 96

Germany

Am Scheid 1

57290 Neunkirchen

Tel : +49 2735 6588580

Spain

C/ Velazquez, N. 80 – 5 IZ

28001 Madrid

Tel : +34 673 234 296