Intralogistics: its growth, its benefits for the supply chain and its future challenges in the era of Industry 4.0

Summary of the article

Intralogistics manages the internal flows of goods and information, optimizing processes such as inventory management and shipping. Through automation and AI, it enhances supply chain performance by reducing errors and increasing flexibility. In the era of Industry 4.0, it evolves to address environmental and economic challenges by integrating smarter and more sustainable solutions.

01. Definition of intralogistics

Intralogistics refers to the management of internal flows of goods, materials and information within a company’s facilities. It encompasses all planning, organisation, control and execution activities related to the movement and storage of goods in a warehouse, factory or distribution centre.

Often overlooked in overall supply chain strategies, intralogistics has quietly established itself as an essential pillar of business success: by optimising the flow and processing of goods, it enables companies to increase their efficiency, productivity and competitiveness.

Yet intralogistics remains an often misunderstood field. Let’s take a look at its growth, its advantages, and the challenges and opportunities that await us in the era of Industry 4.0.

02. Origins linked to the rise of industrial production

The origins of intralogistics date back to the early 20th century, when the industrial revolution necessitated the development of more complex systems for inventory management and materials handling. Intralogistics was therefore born to meet the new demands of mass production.

Over the decades, intralogistics has evolved continuously, incorporating the latest technological advances. The e-commerce boom in the early 2000s marked a turning point, making intralogistics a full-fledged performance driver.

Since then, intralogistics has become a real competitive issue, forming part of an overall economic strategy. It is no longer limited to simple warehouse management and is now integrated into the entire supply chain, connecting suppliers to end customers.

With the advent of automation and IT systems, intralogistics is opening a new chapter in its history and is becoming fully integrated into Industry 4.0.

With an annual growth rate of around 10.4%, the UK intralogistics market is expected to reach approximately US $6.42 billion by 2030. (Source: Next Move Strategy Consulting)

Modern intralogistics solutions now rely on artificial intelligence and robotics to enhance connectivity and flexibility, enabling them to adapt to changing demand and disruptions in the supply chain.

03. What activities does intralogistics cover?

Intralogistics aims to optimise the flow of goods and information to ensure efficient and profitable operations. It encompasses the following activities:

- Receiving and inspection: Incoming goods are processed, recorded and integrated into the logistics system.

- Inventory management: Goods are stored in appropriate locations according to their nature and turnover rate.

- Order preparation and processing: Goods are removed from stock, sorted, packaged and labelled before shipment.

- Shipping: goods are temporarily stored according to their destination and delivery order before being loaded onto trucks.

- Returns management: once received, goods are recorded and repackaged before being reintegrated into the system.

Each step requires rigorous computerised traceability in order to automate data collection and processing and adapt processes accordingly.

04. The benefits of intralogistics for supply chain performance

Process optimisation

Processes are streamlined and rationalised, from stock management to order preparation and dispatch.

Increase your productivity

intralogistics increases the overall productivity of operators and equipment by automating and optimising workflows

Enhanced flexibility

the connectivity of systems enables decision-makers to react quickly to fluctuations in demand and to adapt stocks and processes as required.

Error reduction

intralogistics reduces human error and increases precision by automating repetitive tasks.

Better traceability

IT technologies and systems such as WCS, barcodes and RFID provide real-time visibility of all warehouse processes and goods.

Cost reduction

By optimising storage space, reducing error rates and order processing times, intralogistics helps to minimise overall supply chain costs.

05. Towards smarter, more sustainable intralogistics

Intralogistics is a rapidly evolving sector that truly reflects our society and our consumption habits. With the emergence of the green supply chain and the connected industry, it is reinventing itself and embracing new challenges, including:

- The evolution of consumer habits, with customers becoming increasingly demanding regarding product availability and delivery speed. Nearly half of online shoppers are likely to abandon their cart if the delivery time is considered too long.

- Intensified competition, driven further by the technology race across all sectors.

- Environmental challengesEnvironmental concerns are prompting companies to adopt more sensible and sustainable intralogistics solutions. In the UK, the warehousing and transport sector consumes approximately 10kWh of energy annually per business, with lighting accounting for around 65% of this energy use. (Source : Yu Energie)

To address these challenges, intralogistics is turning to Industry 4.0 solutions:

– Automation : Automated systems, such as AS/RS (Automated Storage and Retrieval Systems), help streamline processes and reduce order processing times while adjusting production in real time.

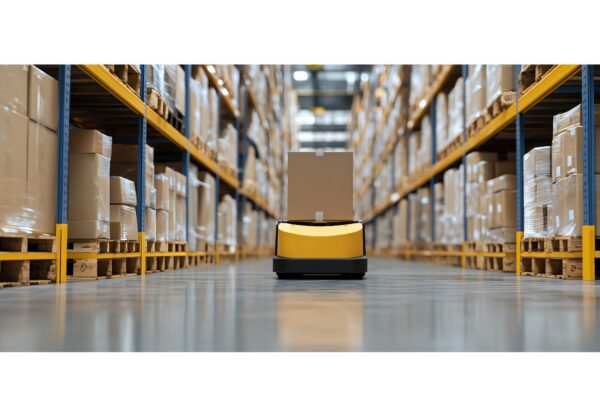

– Robotics: By handling the most repetitive or strenuous tasks, robotic arms, AGVs (Automated Guided Vehicles), and AMRs (Autonomous Mobile Robots) free up operators to focus on higher value-added tasks.

– IT Systems: Thanks to software such as WES, WMS, and WCS, which incorporate artificial intelligence, warehouses can now monitor their flows in real time and anticipate the impact of their decisions using predictive tools like digital twins.

– Energy efficiency: New energy-efficient technologies, such as LEDs and motion sensors, along with the use of recycled materials by manufacturers, enable companies to achieve significant cost savings while being more environmentally friendly.

Download our practical guide: The 7 Major Challenges of Intralogistics and How to Overcome Them

About the Author – Frédéric Cousin

Frédéric Cousin works at Transitic as Sales Manager for Intralogistics & WCS. With significant experience in the supply chain sector, Frédéric spent over 10 years with several well-known software vendors. He also held a logistics manager position for 7 years.

Subscribe to our newsletter

A concentrated dose of intralogistics! Discover our latest business cases, videos, and news.

Related Articles

#connectedintralogistics

France

96 Bd du Petit Quinquin

CRT 1 – 59812 Lesquin

Tél. : +33 (0)3 20 87 66 96

Germany

Am Scheid 1

57290 Neunkirchen

Tel : +49 2735 6588580

Spain

C/ Velazquez, N. 80 – 5 IZ

28001 Madrid

Tel : +34 673 234 296