Transitic x Sifam

Transitic equips Sifam with integrated, connected software to manage its flows

To meet the needs of this fast-growing company, we combined all our expertise to come up with an innovative solution where robots and people work together to improve working conditions and productivity.

Project

Mechanical installation, automation and management via Open WCS

Client

Sifam Group

Location

Provence Alpes Côtes d’Azur, France

The client

The SIFAM group is one of the key players in the European distribution of motorbike and scooter parts from the leading brands. SIFAM has also developed its own range of technical products.

The project

To ensure its continued growth, SIFAM chose our connected conveyor system to optimise the preparation and dispatch of its orders.

The solution had to be adapted to the existing ERP and integrate a new WMS software package for warehouse management and control of all flows, from supplier reception to delivery of parcels to carriers.

The solution

The solution devised by TRANSITIC combines mechanical engineering, automation and IT, and consists of a network of automatic conveyors attached to an IT system incorporating upgradeable WMS software and OpenWCS.

The installation comprises :

– Roller conveyors and a belt conveyor arranged in parallel.

– An extendable conveyor for loading and unloading lorries.

– A machine for sorting shipping cartons.

– An automatic strapping machine.

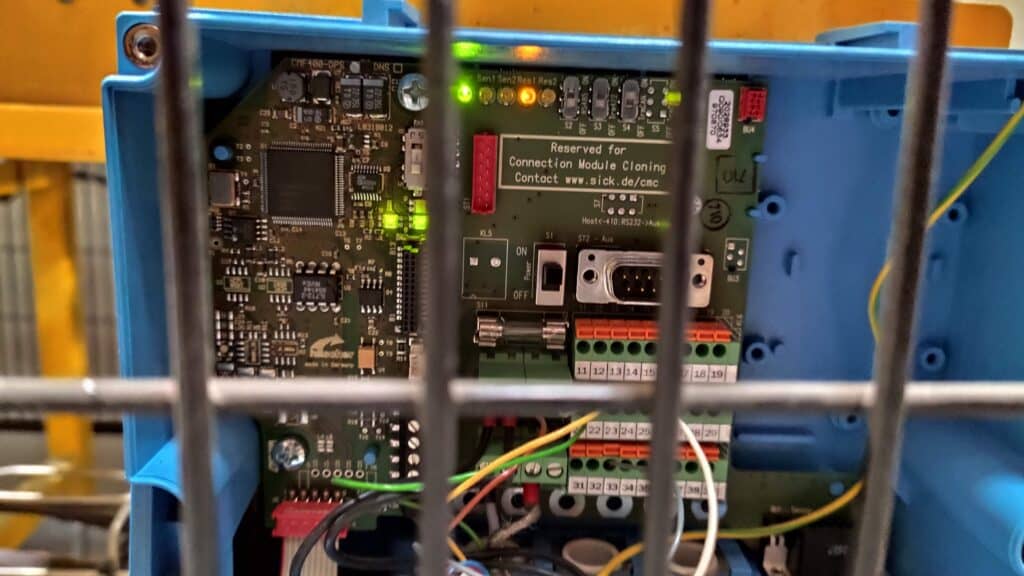

– An omni-directional barcode reader.

Our customer benefits from a 360° view of its warehouse management and precise control of its activity thanks to SCP (Supply Chain Pilot) monitoring. The resulting productivity gains will enable SIFAM to achieve its planned growth.

The key systems of the installation

Barcode reader

The barcode reader, or scanning device, is an essential tool for traceability. Positioned at key points along the order process, it accurately identifies cartons and items, enabling optimal sorting, routing, or assembly based on their type or destination.

Extendable conveyor

The extendable or telescopic conveyor offers a modular setup, making it ideal for adapting to increased goods handling or facilitating truck unloading. It serves as a link between two machines and helps maintain a high production rate.