How to transition from reactive or preventive maintenance to predictive maintenance capable of anticipating failures and maximizing the productivity of automated warehouses?

Summary of the article

Predictive maintenance transforms the management of industrial and logistics equipment by leveraging real-time data to anticipate failures before they occur. It relies on IIoT, CMMS, RFID and the digital twin to collect, analyze and exploit information. By reducing downtime and maintenance costs, it improves productivity.

In warehouses where automation structures all flows, both corrective and preventive maintenance quickly reach their limits: the former intervenes too late, the latter sometimes without any real necessity. Predictive maintenance marks a turning point. By leveraging operational data, it identifies weak signals, anticipates failures, and triggers intervention at the optimal moment. A shift that transforms maintenance — previously a simple cost center — into a direct lever for productivity.

01. What is predictive maintenance?

Predictive maintenance should be understood within a logical progression, as it represents a specific level of maturity in industrial maintenance:

- Corrective maintenance is the most basic: repairs are made once a failure has occurred. It is often costly and a source of disorganization.

- Preventive maintenance involves intervening according to a pre-established schedule, regardless of the actual condition of the machine. While it provides reassurance, it nevertheless generates interventions that are sometimes unnecessary.

- Predictive maintenance relies on real-time monitoring of equipment condition to intervene at the right moment. The goal is to detect the warning signals of a failure before it occurs.

- Prescriptive maintenance is the most advanced stage: it predicts the failure and automatically recommends the action to take to avoid it, taking into account operational constraints, available spare parts stock, and the production schedule.

Predictive maintenance therefore rests on three fundamental pillars: real-time data collection, their analysis, and the decision to intervene at the optimal moment.

According to a study by Deloitte, predictive maintenance can reduce maintenance costs by 25 to 30%, decrease unplanned downtime by up to 70%, and increase equipment lifespan by 20 to 40%. At the scale of a logistics warehouse, one hour of downtime can represent several tens of thousands of euros in losses, not to mention the impact on customer satisfaction and delivery deadline compliance.

02. The technologies at the heart of predictive maintenance

Predictive maintenance relies on a fundamental condition: the ability to collect real-time data on equipment condition. This is precisely the role of the IIoT (Industrial Internet of Things).

The central role of the IIoT

Connected sensors are installed directly on machines and systems — conveyors, stacker cranes, robotic arms, sorting systems… They continuously measure a multitude of parameters: vibrations, temperature, electrical current consumption, pressure, wear level… Cross-referenced and analyzed over time, these signals reveal trends and anomalies that a human alone could not detect.

The IIoT is therefore an essential element of any predictive strategy. Without quality data, no software could produce reliable predictions.

Supply Chain software and CMMS: centralizing to make better decisions

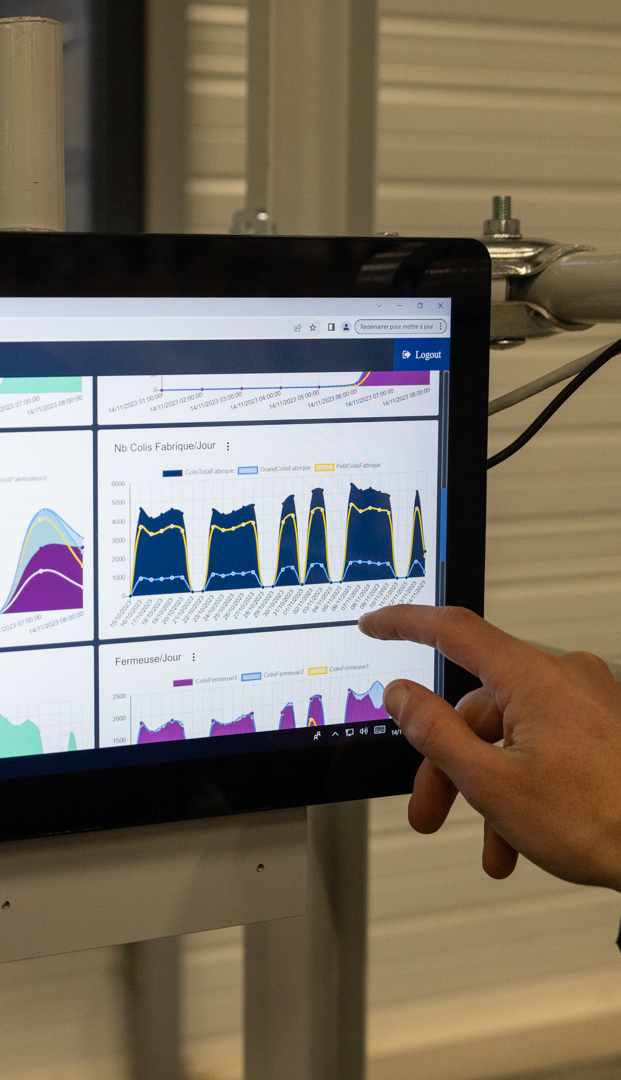

Once the data has been collected, supply chain software and CMMS (Computerized Maintenance Management System) platforms enable it to be used effectively.

They centralize all data from sensors, analyze it alongside the history of failures and interventions, and automatically generate work orders when an alert threshold is crossed. Maintenance teams thus have a unified, real-time view of the health status of their equipment fleet.

The contribution of artificial intelligence and machine learning is decisive here. The algorithms learn to recognize the precursor patterns of failures and their accuracy improves continuously.

03. The Digital Twin: simulating to anticipate

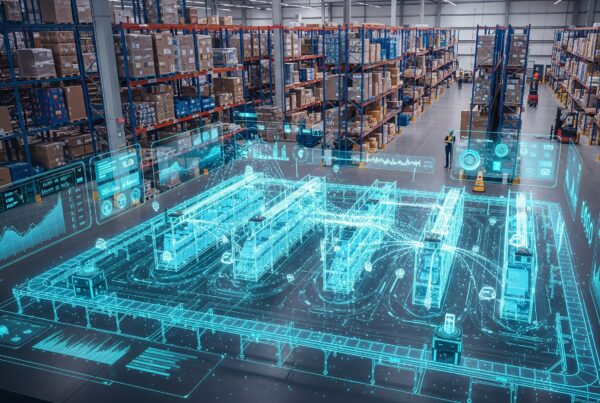

The digital twin represents a major advancement in predictive maintenance. It is a virtual and dynamic replica of a piece of equipment or an entire warehouse, fed in real time by data from physical sensors.

Teams can simulate degradation scenarios, test maintenance strategies, and evaluate the impact of a modification before deploying it in the field. It allows, for example, monitoring the wear of a conveyor system based on millions of completed cycles, or anticipating the replacement of a component before it fails.

It is a powerful decision-making tool that considerably reduces operational risk.

04. RFID and equipment traceability

Often underestimated, RFID (Radio Frequency Identification) plays an important role in predictive maintenance by enabling precise traceability of each part and each piece of equipment throughout its lifecycle.

Each component is identified by an RFID tag that records its entire history: commissioning date, number of cycles completed, interventions carried out, parts replacements… This data feeds directly into predictive algorithms, which thus have precise context to refine their analyses and reduce false alerts.

05. Barriers to adoption: challenges not to be underestimated

Despite its obvious advantages, predictive maintenance cannot be improvised.

Investment cost

The initial investment cost remains significant: sensor deployment, software integration, team training. While the return on investment is generally rapid, the upfront financial effort can be a barrier for small and medium-sized businesses.

Data quality

Data quality is a critical issue. Poorly positioned sensors, incomplete data, or poorly interconnected heterogeneous systems can distort analyses and generate irrelevant alerts and, over time, erode team confidence in the tool.

Change management

Change management is perhaps the most frequently underestimated challenge. Maintenance teams must develop new skills in data analysis, alert interpretation, and the use of new tools. Without appropriate support, the risk of rejection is real.

Interoperability

Finally, interoperability between different systems often represents a complex technical challenge, particularly in warehouses equipped with older machinery.

These barriers are real, but they are not insurmountable — provided the right support is in place. Transitic guides its clients through the implementation of effective predictive maintenance, intervening on equipment connectivity, retrofit and automation of machines requiring refined performance monitoring, as well as on the integration of supply chain software in order to fully leverage the collected data.

About the Author – Adrien Gislain

Adrien Gislain has been working at Transitic as Customer Solutions Manager since 2021. With over 10 years of experience in logistics, both in France and internationally, he is recognized as an expert in Intralogistics 4.0 and robotics.

Subscribe to our newsletter

A concentrated dose of intralogistics! Discover our latest business cases, videos, and news.

Related Articles

#connectedintralogistics

France

96 Bd du Petit Quinquin

CRT 1 – 59812 Lesquin

Tél. : +33 (0)3 20 87 66 96

Germany

Am Scheid 1

57290 Neunkirchen

Tel : +49 2735 6588580

Spain

C/ Velazquez, N. 80 – 5 IZ

28001 Madrid

Tel : +34 673 234 296