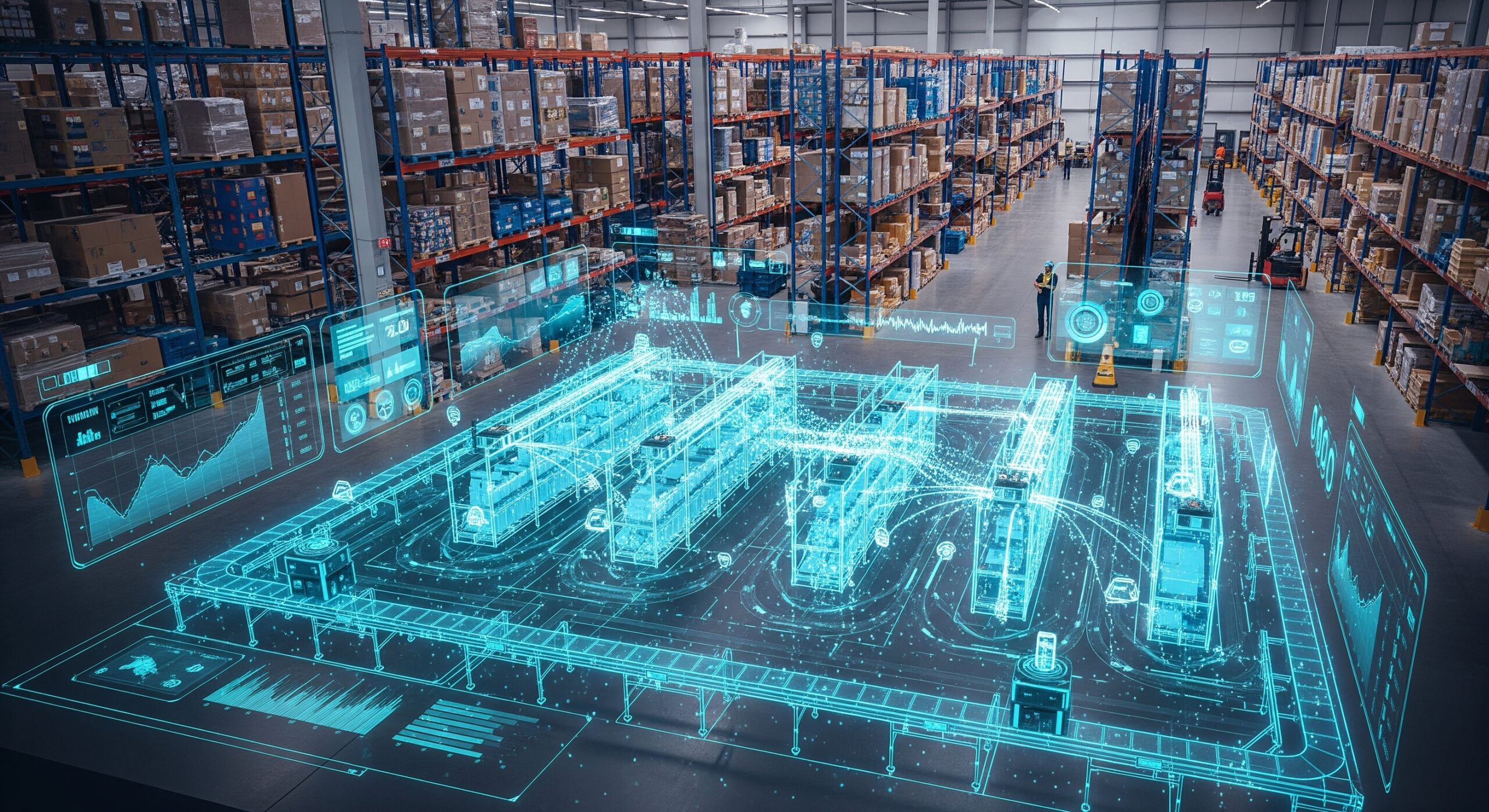

Optimizing and anticipating intralogistics performance with the Digital Twin

Originally developed for aerospace and automotive industries, the digital twin quickly proved its potential as an industrial optimization tool. These sectors adopted it to model complex systems, test maintenance scenarios, and anticipate critical failures.

Today, this technology goes far beyond design offices and is making its way into warehouses. It represents a turning point in intralogistics, on par with robotization and artificial intelligence. Professionals see it as particularly well-suited to the many challenges they face: product proliferation, faster processing speeds, zero-defect requirements, seasonal fluctuations in volumes, shorter delivery times, and more.

Transitic invites you to dive deeper into this revolution and the advantages it brings.

Summary of the article

The digital twin optimizes intralogistics by providing a dynamic and connected virtual replica of warehouses, enabling continuous testing, anticipation, and optimization of operations. It is a valuable decision-making tool that enhances productivity, reduces costs, and simplifies maintenance while strengthening business resilience against unexpected events. From design to operation, it transforms logistics into a strategic driver of innovation and performance.

01. A rapidly accelerating market

The digital twin is generating increasing interest among professionals seeking both predictive and agile management tools. According to a Research and Markets study, 42% of executives already acknowledge its tangible benefits, while 59% plan to integrate it into their processes by 2028.

Projections point toward massive adoption in the coming years. According to Fortune Business Insights, the global digital twin market could reach €242 billion by 2032, with an average annual growth rate of nearly 40%.

These figures illustrate a profound transformation: the digital twin is no longer a mere experimental innovation but now plays a central role in the design, management, and optimization of tomorrow’s warehouses.

02. What is a Digital Twin in intralogistics?

A digital twin is a virtual and intelligent replica of a warehouse, a system, or a logistics process. By reproducing both the physical and functional characteristics of a site — whether already in operation or still in design — it allows observation, testing, and optimization of operations without disrupting real-world activities.

This constantly updated digital model provides a comprehensive and dynamic view of intralogistics operations. Unlike traditional 3D simulations or static layouts, it stands out thanks to its ability to integrate real-time data, layout adjustments, unexpected events, and technological evolutions. It evolves alongside reality while enabling scenario testing in advance.

Several types of digital twins apply to logistics:

Component Twin

Focuses on individual elements or interdependent parts of one or more pieces of equipment.

System Twin

Represents a larger set, such as a sorting comb or a defined area of the warehouse.

Process Twin

The most comprehensive type, modeling the entire logistics installation and its operational flows.

03. How the Digital Twin works: From data collection to warehouse optimization

The functioning of a digital twin relies on a continuous cycle of data collection, modeling, simulation, and optimization:

- Data Collection: Starts with the integration of data from multiple sources—warehouse layouts, operational history, KPIs, real-time IoT sensor data, and management systems (WMS and WCS).

- Model Creation and Updating: This data builds a detailed, accurate, and constantly updated replica of the physical warehouse.

- Simulation and Testing : The digital twin becomes a true virtual laboratory, simulating a wide range of scenarios: activity peaks, breakdowns, new constraints, etc.

- Continuous Monitoring: On a daily basis, it provides permanent monitoring by comparing virtual and real behaviors simultaneously.

- Optimization and Continuous Improvement: Through analysis and forecasting, it delivers valuable insights for global warehouse management.

The digital twin doesn’t replace warehouse management systems but complements and strengthens them. It unleashes its full potential when interconnected with the warehouse’s “nervous systems”:

WMS (Warehouse Management System)

Uses its data to offer a dynamic visualization of the warehouse and flows, enabling impact assessment of decisions made through the WMS.

WCS (Warehouse Control System)

Directly leverages operational data from the WCS to simulate and optimize the performance of automated machines (conveyors, robots, etc.).

04. Key benefits of the Digital Twin for intralogistics and warehouses

The digital twin transforms warehouse management by providing multi-level benefits for global operational optimization:

- Enhanced Execution Quality: Thanks to continuous and real-time monitoring of operations.

- Faster Deployment: For equipment and overall logistics systems.Gain de temps au déploiement

- Better Decision-Making: Through simulations and projections based on data analysis and artificial intelligence.

- Significant Cost Savings: By enabling more informed strategic decisions.

- Simplified Maintenance: With early detection and anticipation of failures.

- Maximized Productivity: In synergy with warehouse management software.

Additionally, the digital twin provides tangible value at every stage of an intralogistics project, benefitting both the client and the integrator:

During Design

Upstream of a project, it models and designs installations with unmatched precision. It serves as a powerful visualization tool to simulate flows, assess layout and equipment efficiency, and validate design choices from the outset. This approach helps identify and eliminate bottlenecks long before physical implementation, reducing costly errors and delays.

During Deployment

In the implementation phase, the digital twin acts as a dynamic reference. It ensures compliance with plans and allows real-time technical adjustments if unexpected issues or improvement opportunities arise.

During Operation

Once the warehouse is running, the digital twin becomes an intelligent, proactive dashboard. It analyzes live performance and enables simulations without disrupting actual operations. This ensures continuous optimization of flows, ongoing productivity improvement, and greater resilience to market fluctuations and uncertainties.

A proactive approach to intralogistics through the Digital Twin

The digital twin is a game-changer in intralogistics, offering a smarter, more agile, and more resilient vision of warehouse operations. With this virtual, dynamic, and connected replica of the real environment, logistics management shifts from a reactive to a proactive approach, where anticipation and continuous optimization become the standard.

Beyond productivity gains and cost savings, the digital twin primarily provides a new perspective on logistics management. It allows testing, validation, and adjustment of decisions before implementation, while maintaining real-time visibility across all operations. It is a powerful tool to transform logistical constraints into innovation opportunities, helping companies make the right decisions at the right time.

About the Author – Franck Tiablikoff

Franck Tiablikoff is Sales Manager for Process at Transitic. With 30 years of industry experience, he has overseen hundreds of automation projects for both SMEs and major corporations.

Subscribe to our newsletter

A concentrated dose of intralogistics! Discover our latest business cases, videos, and news.

Related Articles

#connectedintralogistics

France

96 Bd du Petit Quinquin

CRT 1 – 59812 Lesquin

Tél. : +33 (0)3 20 87 66 96

Germany

Am Scheid 1

57290 Neunkirchen

Tel : +49 2735 6588580

Spain

C/ Velazquez, N. 80 – 5 IZ

28001 Madrid

Tel : +34 673 234 296