Summary of the article

Cobotics is a rapidly growing market. Over 30% of warehouses are already using it. Cobots work alongside human operators, assist them, and adapt in real time thanks to technologies like AI and 3D vision. Deployed in sectors such as automotive and agri-food, they enhance productivity, safety, and working conditions. With the rise of cognitive cobotics, these machines are becoming capable of learning, anticipating, and cooperating — paving the way for a new era of human-robot collaboration.

Faced with challenges of flexibility and productivity, supply chain professionals are increasingly turning to cobotics.

Already adopted in over 30% of logistics warehouses for tasks such as sorting or material handling (source: Global Growth Insights), it appeals due to its ability to assist operators without replacing them, while adapting to complex environments like automotive, electronics, or pharmaceuticals.

Transitic invites you to take a closer look at what a cobot is and its possible fields of application.

01. What is a cobot?

Cobotics is the most promising industrial technology of the past decade. The term 'cobot' officially refers to a 'non-autonomous robot working in direct collaboration with a human, with the aim of increasing productivity and reducing the strain of manual tasks.

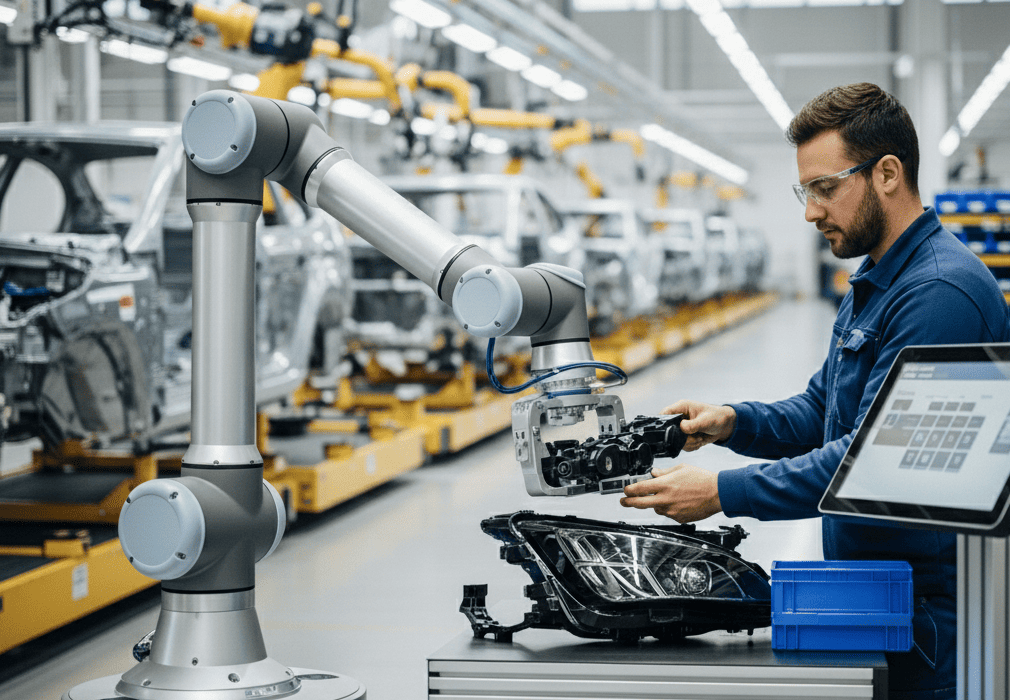

A contraction of the words “robot” and “collaborative”, the cobot is designed to assist humans and work directly with them. It in no way supplants the human being, but rather provides him with safety, comfort and precision in his work, reducing the risk of injury at the same time.

Unlike traditional industrial robots, which are often isolated in secure areas, cobots safely operate in shared spaces alongside human operators. They are developed according to the ISO/TS 15066 standard, in effect since 2016, which sets safety requirements for human-robot interactions. This standard specifically requires:

- Contact detection through integrated sensors

- A limited movement speed near humans

- Automatic stop in case of obstacle or danger

- Operation without physical barriers

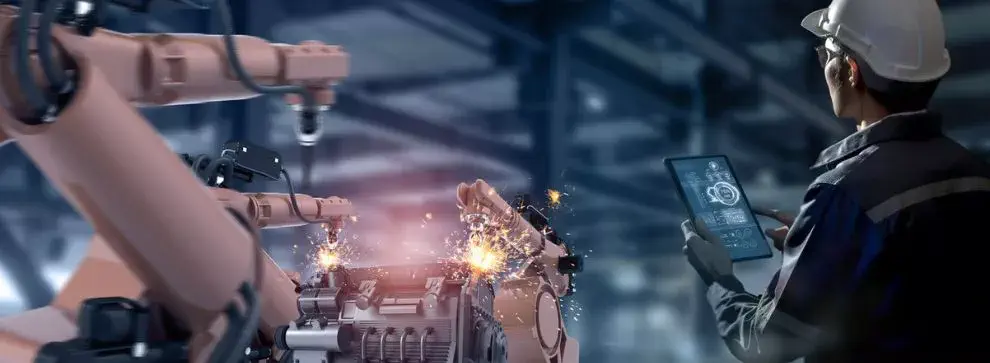

Thanks to technologies such as artificial intelligence, laser sensors, and 3D cameras, cobots can adapt their tasks in real time based on their environment.

And the results speak for themselves: according to a MIT study, human-cobot teamwork achieves an 85% increase in productivity compared to tasks performed solely by a human or an industrial robot.

02. A booming market

The global cobotics market is continuously growing and is expected to exceed 10 billion dollars by 2027, according to a study by Research and Markets.

In Europe, the countries best equipped with cobots are Germany, Italy, and France (source: IFR).

Cobots are now finding their place in a variety of industrial sectors, each leveraging their specific capabilities.

- The automotive industry is the primary user sector, thanks to standardized applications such as assembly, welding, and inspection.

- The electronics industry leverages the precision and flexibility of cobots to handle sensitive components with the utmost accuracy.

- The food industry uses them to automate repetitive tasks such as packaging and sorting, while meeting hygiene requirements.

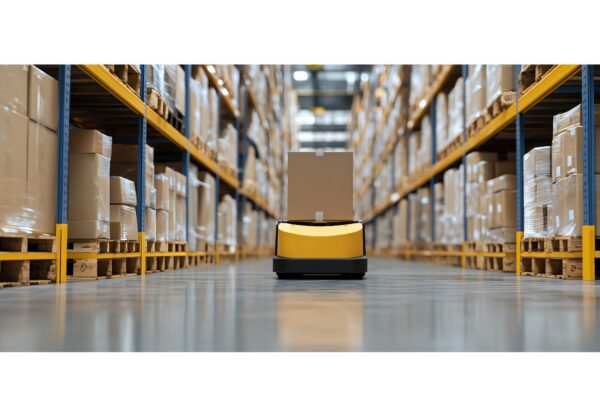

- Logistics is rapidly adopting cobots to boost productivity in order picking, material handling, and palletizing.

03. The different types of industrial cobots

There are four main levels of interaction in cobotics, classified according to the robot’s degree of autonomy:

More than 50% of the cobots deployed in warehouses in recent years are AMRs (Autonomous Mobile Robot), primarily used to transport goods along predetermined paths.

04. Cobots: their benefits for your warehouse

The greatest challenge, and the main factor in the success of this formidable technology, undoubtedly lies in the training, skills development and support of individuals in mastering cobotics.

Cobots are particularly well-suited to logistics: they take up very little space and are used for packaging, pick&place, packing, etc.

With an average return on investment of one year, the cobot is proving to be a rapidly profitable investment.

By freeing themselves from certain tasks, operators can concentrate on higher value-added activities.

By reducing the drudgery and repetition of “thankless” tasks, the cobot helps to improve employee health and reduce work stoppages.

05. Towards cognitive cobotics

Current developments in cobotics go beyond simple automation.

They now incorporate artificial intelligence to create smart and interactive systems. The goal is to design collaborative robots capable of understanding human intentions, interpreting gestures or facial expressions, and eventually anticipating certain actions. Thanks to deep learning and imitation learning, they will be able to adapt to complex environments and adjust their behavior in real time without the need for reprogramming.

About the Author – Adrien Gislain

Adrien Gislain has been working at Transitic as Customer Solutions Manager since 2021. With over 10 years of experience in logistics, both in France and internationally, he is recognized as an expert in Intralogistics 4.0 and robotics.

Subscribe to our newsletter

A concentrated dose of intralogistics! Discover our latest business cases, videos, and news.

Related Articles

#connectedintralogistics

France

96 Bd du Petit Quinquin

CRT 1 – 59812 Lesquin

Tél. : +33 (0)3 20 87 66 96

Germany

Am Scheid 1

57290 Neunkirchen

Tel : +49 2735 6588580

Spain

C/ Velazquez, N. 80 – 5 IZ

28001 Madrid

Tel : +34 673 234 296