AGV vs AMR: Understanding the key differences

Summary of the article

Mobile robots play a central role in warehouse automation. Among them, AGVs (Automated Guided Vehicles) and AMRs (Autonomous Mobile Robots) stand out due to their architecture and embedded intelligence. AGVs follow fixed paths suited to repetitive flows, while AMRs provide autonomous and adaptive navigation, ideal for environments shared with human operators. This article compares these two technologies, their pros and cons, and offers guidance for choosing the solution best suited to your company.

01. Role of Mobile Robots in Automation

In a context where warehouse automation is booming, mobile robots now play a central role, whether for transporting packages or supplying production lines.

There are two main families of autonomous mobile vehicles: AGVs (Automated Guided Vehicles) and AMRs (Autonomous Mobile Robots). While they share similar functions (autonomous movement, internal transport), these two technologies differ significantly in architecture, embedded intelligence, and adaptability.

Choosing between AGV and AMR can have a major impact on the efficiency, flexibility, and profitability of a facility.

02. Market Opportunities

Before diving into specifics, here are some figures to understand the stakes:

- The combined AGV and AMR market is estimated at around USD 20 billion by 2028, with an installed base of 2.7 million units expected. ( source : GlobeNewswire )

- For 2024-2030, the market is projected at approximately USD 22 billion, with a growth rate of 30% for AMRs and 18% for AGVs.

- Penetration rates are still low in some countries.

In other words: these technologies are no longer marginal, but they are not yet fully widespread, meaning development opportunities remain enormous.

03. AGV: The Pioneer of Mobile Robotics

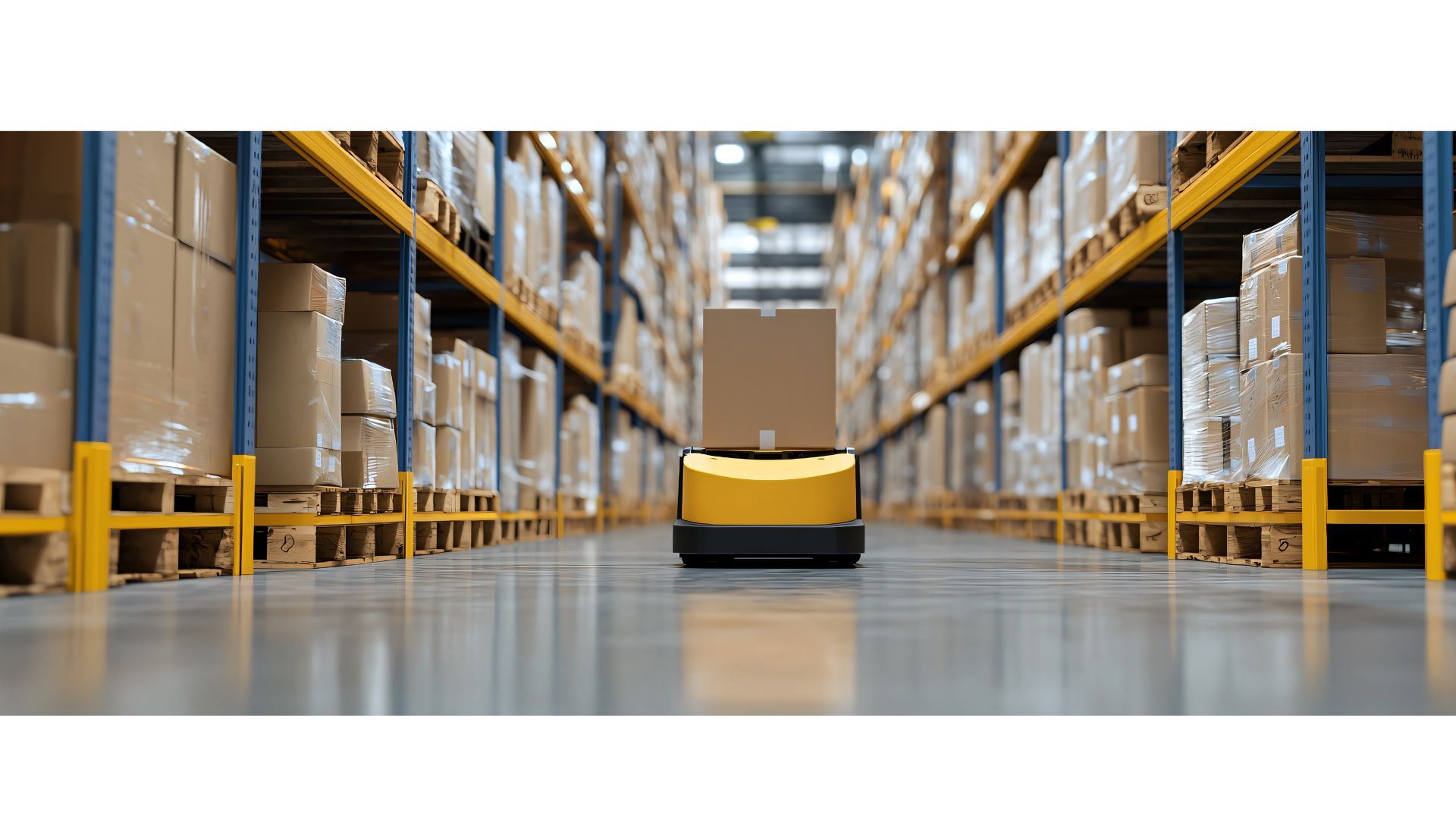

Autonomous mobile robot carrying pallets in a modern warehouse for efficient logistics.

On each trip, the AGV follows this fixed path, often in a controlled environment (factory, warehouse) with little variability. Guidance methods include:

- Magnetic tape (or special adhesive tape) on the floor

- Buried wire in the floor

- Laser reflectors

- Rails or dedicated structures

When an AGV encounters an unexpected obstacle (a fallen box, a misplaced pallet…), it stops and waits for the obstacle to be cleared.

Advantages

- Stable and proven technology: many AGV installations have been operating for years in industry.

- High level of safety: the path is known, controlled, with limited maneuvering.

- Suitable for repetitive environments with few changes (e.g., automotive production lines).

- Initial cost often lower than a highly sophisticated AMR system.

Disadvantages

- Limited flexibility: as paths are predefined, any layout change requires reprogramming or physical adjustments (moving tapes, wiring…).

- Dependence on physical guidance: tape or wire degradation can cause stops or navigation errors.

- Frequent stops in case of obstacles: a box, pallet, or person on the path can interrupt the flow entirely.

- Less seamless integration with operators: AGVs are designed for dedicated areas, less suited for human-robot coexistence.

- Limited scalability: adding new routes or vehicles often requires significant technical adjustments.

In summary: AGVs follow a fixed plan : they do not adapt.

04. AMR: The Next Generation of Intelligent Robots

AMRs are the next generation. They are no longer constrained to a fixed path and feature intelligent autonomous navigation: environment mapping, real-time localization, trajectory planning, and obstacle avoidance. They use technologies such as:

- SLAM (Simultaneous Localization and Mapping)

- LiDAR sensors, 3D cameras, ultrasonic sensors

- Sensor fusion to recognize zones, obstacles, and humans

- Fleet and task management software

An AMR always knows where it is, where it needs to go, and the best path to get there.

Advantages

- High flexibility: workflows, zones, and tasks can be changed without a complete physical system overhaul.

- Can avoid obstacles and adapt its route in real time: better integration in environments shared with operators.

- Usually faster installation: no need for tapes or wires, often “plug & play.”

- Can manage multiple missions and prioritize according to needs.

- Improves operational safety as it is designed to detect and react to humans or unexpected objects

Disadvantages

- Higher initial investment: embedded technology (sensors, software, AI) makes AMRs more expensive upfront.

- Software complexity: fleet management, mapping, and software maintenance require advanced technical skills.

- Dependence on connectivity: AMRs require a stable network (Wi-Fi, 5G…) for optimal performance.

- Sensitivity to highly changing environments: although adaptable, some AMRs may lose performance if visual landmarks or lighting change frequently.

- Continuous maintenance and updates: sensors and software must be calibrated and updated regularly to ensure accuracy and safety.

05. Which Robot to Choose for Your Business?

The right choice depends primarily on your logistics objectives, work environment, and automation strategy:

-

- If your workflow is stable and repetitive, the layout rarely changes, and human operators do not freely circulate in the same areas as vehicles: an AGV is a relevant, economical, and proven choice.

- Conversely, if you operate in a dynamic site where aisles and flows change, there is high human-robot interaction, and zones or products are frequently modified: an AMR will be a more suitable, scalable investment.

Another factor: scalability. If you anticipate future changes (new flows, expansions, increasing automation), an AMR solution may be more cost-effective in the long term despite a higher initial cost.

A hybrid approach is also valid: for example, an AGV for very stable production lines + an AMR for more variable logistics or picking tasks.

06. Future Perspectives for AMRs and AGVs

Emerging Technologies

The right choice depends primarily on your logistics objectives, work environment, and automation strategy:

Expanding Application Sectors

Human-Robot Shared Spaces

In the near future, most AMRs will be designed to work alongside human operators in less segregated environments, similar to cobots. (Read our article about intralogistics cobotics)

High-Potential Markets

AMRs/AGVs are emerging in sectors such as healthcare, retail, agriculture, mining exploration, and cleaning/inspection services.

07. Challenges and Obstacles to Overcome

While automation technologies and autonomous mobile robots offer real efficiency gains, their deployment also brings challenges that companies must anticipate to ensure successful integration.

Cybersecurity and Connectivity

The rise of smart sensors, 5G, and IoT increases connection points in logistics infrastructures. While hyper-connectivity improves traceability and system communication, it also introduces new cybersecurity risks. Data flows in real time between robots, servers, and management software such as WCS (read the definition of WCS) , making it essential to reinforce security protocols, regularly update systems, and train staff in digital best practices.

Return on Investment

Despite promises of efficiency and flexibility, some installations take time to prove profitability. The higher initial cost of AMRs (compared to classic solutions like AGVs or conveyors) can be a barrier for some companies.

ROI calculation depends on many factors: flow volume, utilization rates, software integration, maintenance, and staff training. A detailed upfront analysis is essential to ensure a measurable and rapid return on investment.

Standards, Safety, and Human-Robot Coexistence

Integrating robots in areas shared with operators imposes new safety requirements. AMRs must detect their environment, anticipate obstacles, and follow strict protocols to ensure safe human-machine coexistence.

International standards (ISO 3691-4, ISO 10218, ISO 13849…) regulate these interactions and define requirements for design, sensors, and emergency stop devices.

Organizational and Human Change

Automation does not only transform equipment; it deeply impacts work organization. Adopting new tools requires process adjustments, staff training, and sometimes restructuring roles.

Strong human support is essential: internal communication, continuous training, and staff involvement from the project design stage. Collective buy-in is key to successfully transitioning to more automated environments.

About the author – Cloé Moreel

Cloé Moreel has been a communications officer at Transitic since 2020. She regularly writes articles on intralogistics, supply chain, and emerging connected technologies.

Subscribe to our newsletter

A concentrated dose of intralogistics! Discover our latest business cases, videos, and news.

Related Articles

#connectedintralogistics

France

96 Bd du Petit Quinquin

CRT 1 – 59812 Lesquin

Tél. : +33 (0)3 20 87 66 96

Germany

Am Scheid 1

57290 Neunkirchen

Tel : +49 2735 6588580

Spain

C/ Velazquez, N. 80 – 5 IZ

28001 Madrid

Tel : +34 673 234 296