A concentrated dose of intralogistics! Discover our latest business cases, videos, and news.

Read all our latest news

Filter

Transitic establishes itself in Spain and secures its first contract

Transitic establishes itself in Spain and secures its first contract

Transitic is back at SITL 2026

Transitic is back at SITL 2026

Meet Transitic at LogiMAT 2026

Meet Transitic at LogiMAT 2026

Roller Conveyors: The Complete Guide to Optimizing Internal Warehouse Transport

Roller Conveyors: The Complete Guide to Optimizing Internal Warehouse Transport

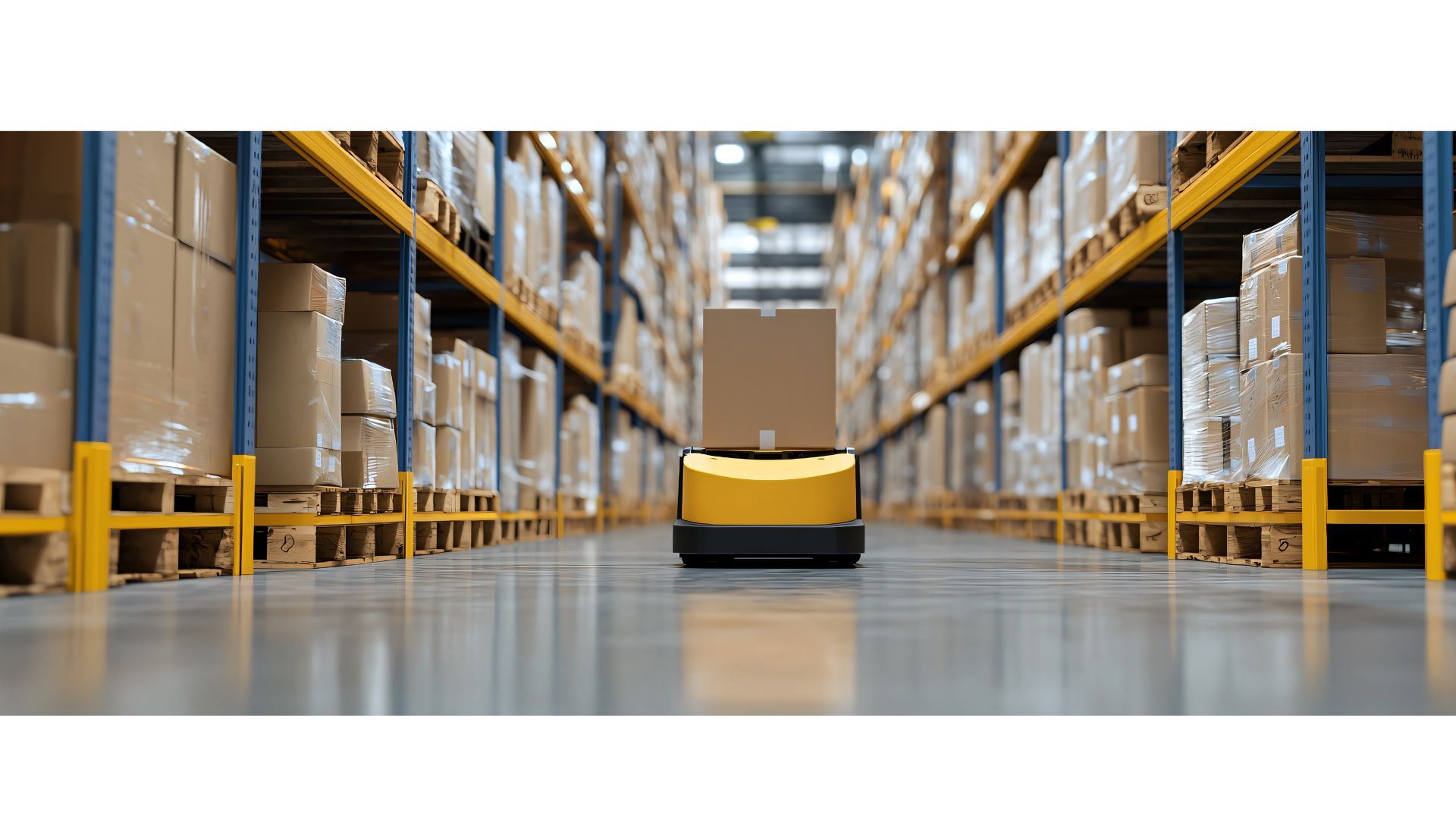

AMR vs AGV: What are the differences between these two mobile robots?

AMR vs AGV: What are the differences between these two mobile robots?

Batch Picking Automation: Our Top 5 Best Systems

Batch Picking Automation: Our Top 5 Best Systems

✉️ Subscribe to our newsletter

#connectedintralogistics

France

Transitic Systems SAS

96 Bd du Petit Quinquin

CRT 1 – 59812 Lesquin

Tél. : +33 (0)3 20 87 66 96

96 Bd du Petit Quinquin

CRT 1 – 59812 Lesquin

Tél. : +33 (0)3 20 87 66 96

Germany

Transitic Systems GmbH

Am Scheid 1

57290 Neunkirchen

Tel : +49 2735 6588580

Am Scheid 1

57290 Neunkirchen

Tel : +49 2735 6588580

Spain

Transitic SL

C/ Velazquez, N. 80 – 5 IZ

28001 Madrid

Tel : +34 673 234 296

C/ Velazquez, N. 80 – 5 IZ

28001 Madrid

Tel : +34 673 234 296